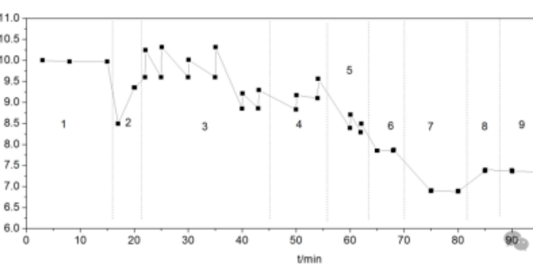

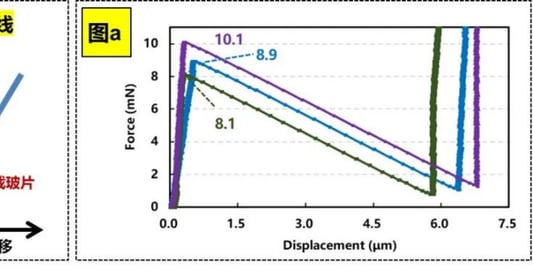

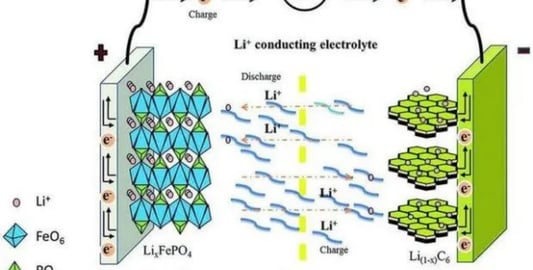

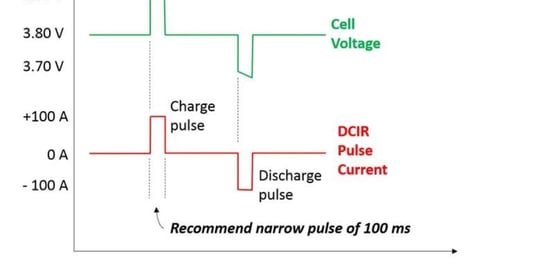

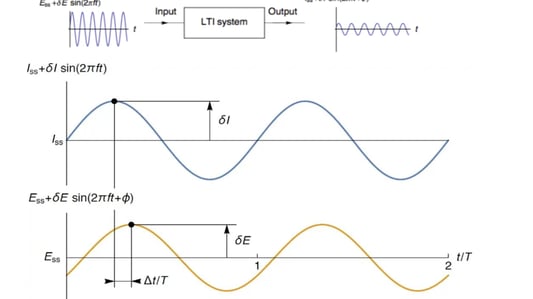

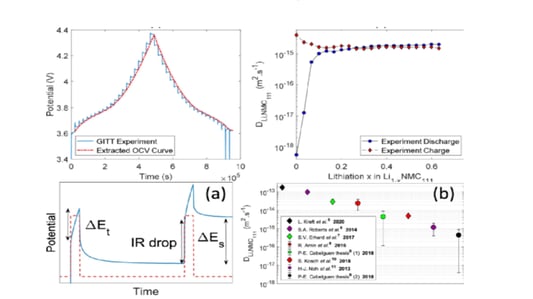

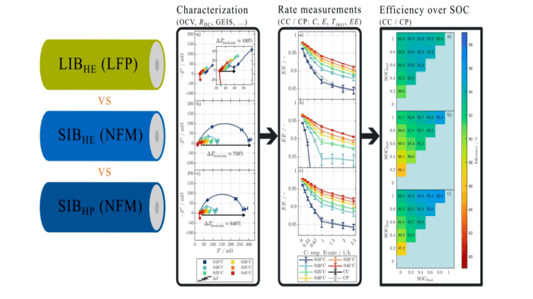

Performance Analysis of lithium iron phosphate battery vs Sodium Ion BatteryAbstractThis article presents a detailed analysis of the electrical performance of commercial lithium iron phosphate batteries and sodium ion batteries. A key focus is on their operation across varying temperature ranges. Research indicates that lithium iron phosphate batteries (LIBs) experience less energy efficiency loss than sodium ion batteries (SIBs) in low state of charge (SOC) conditions, particularly noticeable under constant power conditions. Additionally, SIBs show more substantial dependence on temperature and SOC in terms of resistance and impedance. However, the rate performance of SIBs remains competitive with lithium iron phosphate batteries.Research MethodologyThis study examines three types of commercial 18650 batteries: one lithium iron phosphate battery (LIB) and two sodium ion batteries (SIBHE and SIBHP). Experiments were conducted across temperatures from 10 °C to 45 °C, including open circuit voltage (OCV) measurement, direct current resistance (DCR) measurement, pulse impedance testing, and rate performance assessment. The lithium iron phosphate battery is constructed with a lithium iron phosphate positive electrode and a graphite negative electrode, while the sodium ion batteries feature NaMn1/3Fe1/3Ni1/3O2 positive electrodes and hard carbon negatives.Results: Open Circuit Voltage (OCV)Lithium Iron Phosphate Battery: OCV curve is stable during charge and discharge, leading to minimal voltage variation over wide capacity ranges. Its temperature impact is slight, and both capacity and OCV shape remain relatively unchanged at various temperatures.Sodium Ion Batteries: Display significant voltage changes with capacity increases. Rising temperatures impact the OCV significantly, especially at high SOC.Results: DC Resistance and ImpedanceLithium Iron Phosphate Battery: Exhibits minimal variation in DCR and impedance dependent on SOC and temperature.Sodium Ion Batteries: Show substantial variation in DCR and impedance, particularly significant in low SOC, with high temperature sensitivity.Rate PerformanceLithium Iron Phosphate Battery: Displays robust performance even at high current rates (1C and above), with minor capacity and energy losses.Sodium Ion Batteries: Although competitive, rate performance shows greater dependence on current rate and temperature. SIBHP slightly outperforms SIBHE.Energy EfficiencyLithium Iron Phosphate Battery: Maintains stable energy efficiency across SOC regions, with low SOC showing slight efficiency loss.Sodium Ion Batteries: Efficiency is significantly higher in high SOC regions as opposed to low SOC regions, with efficiency drops at low temperatures.Temperature EffectsLithium Iron Phosphate Battery: Exhibits stable performance with minimal temperature impact.Sodium Ion Batteries: Performance is greatly affected by temperature, more so in lower temperatures causing decreased capacity and efficiency.ConclusionThis comparative study reveals distinct differences between lithium iron phosphate batteries and sodium ion batteries, especially under varying temperature conditions. The efficiency of lithium iron phosphate batteries highlights their suitability for high-efficiency applications, whereas sodium ion batteries require more controlled environments to optimize performance. Studies chiefly focused on 18650 battery configurations; more research is necessary to understand long-term cycling and aging effects.Quote Inquirycontact us

15. March, 2025