Cylindrical battery pole piece: Key Design Insights

Introduction to Cylindrical Batteries

Cylindrical battery pole pieces have established a significant market presence, especially in laptops and electric bicycles. Their popularity is attributed to superior thermal management, structural stability, and suitability for large-scale production using standardized processes. The advent of the 4680 large cylindrical battery has further heightened interest in cylindrical battery pole pieces.

The Challenge of Electrode Bending

One inherent challenge of cylindrical battery pole pieces is the bending of electrodes during the winding process. This bending can lead to mechanical and microstructural deterioration. The curvature of the electrode changes with the radial position, impacting the local negative to positive capacity ratio (N/P ratio). Such variations can compromise battery performance, leading to inconsistent capacity and raising the risk of lithium metal deposition.

Mathematical Concepts of Curvature

Understanding curvature is essential for optimizing cylindrical battery pole piece design. Curvature is defined geometrically, with the curvature circle representing the degree of bending at a specific point. Mathematical calculations define the curvature radius and curvature center, further aiding in cylindrical battery pole piece optimization.

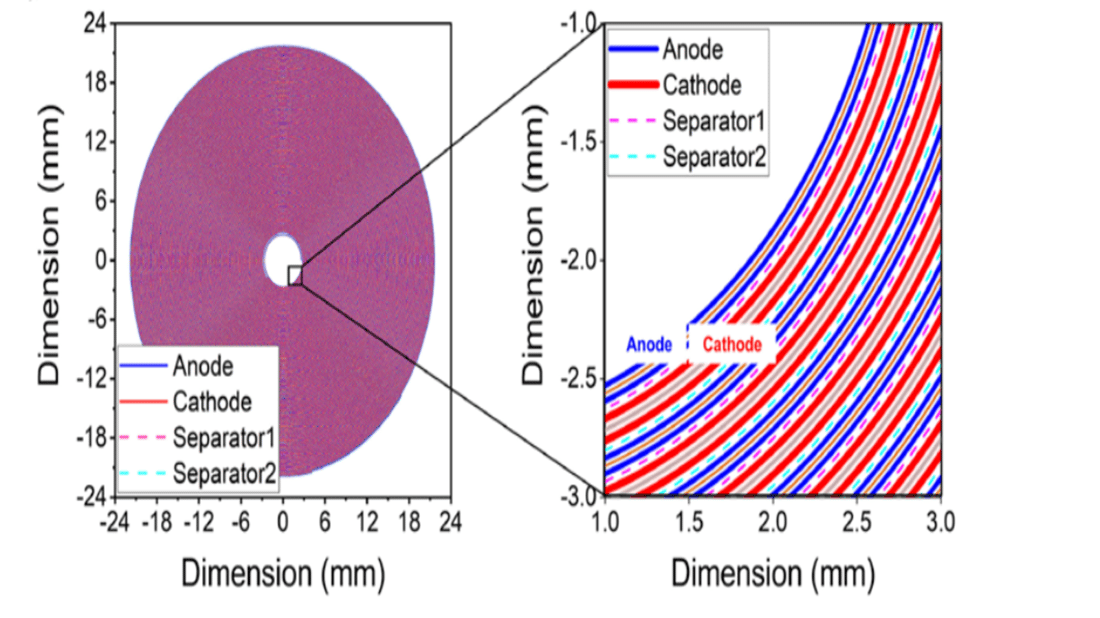

Archimedes' Spiral Representation

In cylindrical battery pole pieces, winding electrodes can be illustrated by Archimedes' spiral lines. The curvature κ of any point on the winding is determined by the polar angle, affecting the spiral parameter of the cylindrical battery pole piece.

Impact of Curvature on Performance

X-ray computed tomography (CT) scans reveal curvature changes within the electrode structure of batteries 21700 and 4680. These changes affect the contact area between the positive and negative cylindrical battery pole pieces, influencing the N/P ratio. Unlike laminated batteries, where the N/P ratio remains uniform, cylindrical battery pole pieces experience contact area variations based on their radial position.

Case Studies and Experimental Insights

Experiments simulating the curvature of cylindrical battery pole pieces demonstrate how varying radii affect electrode performance. Studies highlight that radii below 10 mm result in significant contact area changes, impacting capacity ratios. Conversely, radii above 10 mm show less pronounced effects. The experiments provide insight into enhancing cylindrical battery pole piece designs for optimal performance.

Conclusion: Optimizing Cylindrical Battery Pole Piece Design

Designing cylindrical battery pole pieces with positive and negative surfaces and differing loading capacities ensures a consistent N/P ratio on both sides. This approach enhances the consistency and performance of cylindrical battery pole pieces, making them a vital component in modern battery design.