The Role of Binder in Lithium-Ion Batteries

Understanding Binders in Lithium-Ion Battery Electrodes

In lithium-ion batteries, the binder is a critical polymer compound used in the electrodes. It serves to adhere the active substances of both the positive and negative electrodes to the current collector. The primary role of the binder is to provide a stable bond that maintains both the mechanical structure of the electrode and the electrochemical stability of the lithium-ion battery during both manufacturing and operation.

Essential Qualities of Binders for Lithium-Ion Batteries

- Electrolyte Compatibility: Binders need to be insoluble in electrolytes and avoid chemical reactions within the lithium-ion battery.

- Electrochemical Stability: The binder must remain stable, avoiding oxidation or reduction, especially during the charging and discharging cycles of lithium-ion batteries.

- Processing Performance: Binders should aid in the production of slurry and electrode sheets to benefit the overall processing of lithium-ion batteries.

- Adhesive Performance: Providing robust adhesion is essential to prevent active material detachment in lithium-ion batteries.

Mechanics of Adhesive Bonding in Lithium-Ion Batteries

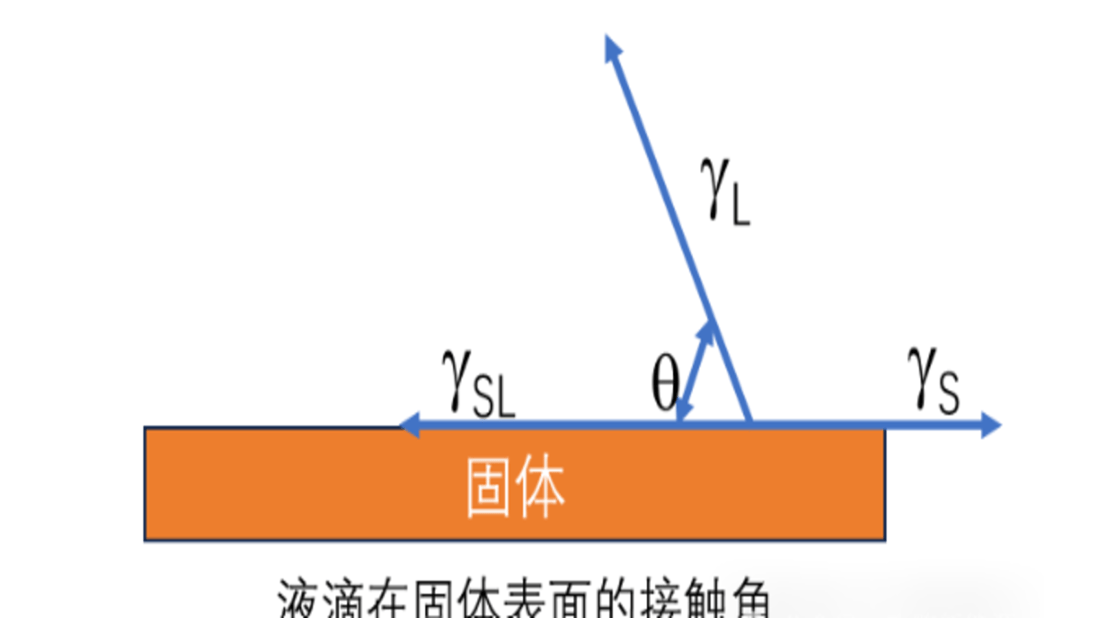

Adhesive bonding in lithium-ion batteries involves a two-step process beginning with wetting, which is essential for adhesion. Wetting refers to the liquid uniformly spreading over the solid surface, driven by surface tension. Following wetting, adhesion forces, encompassing chemical and material adhesion forces, take effect to ensure stability in lithium-ion batteries.

Factors Leading to Adhesive Strength Reduction in Lithium-Ion Batteries

- External forces like shearing and pulling can damage the adhesive strength in lithium-ion batteries.

- A reduction in bonding areas or interface contamination can weaken adhesion within lithium-ion batteries.

- High heat can break molecular chains in adhesives, impacting the adhesive strength crucial for lithium-ion batteries.

Interface Adhesion Influences in Lithium-Ion Batteries

Various factors affect the interface adhesion in lithium-ion batteries including the properties of substrate materials, microscopic characteristics of the bonding interface, and the formulation of the adhesive used. The environmental conditions under which the lithium-ion battery operates, such as temperature and chemical exposure, also play a pivotal role in maintaining effective adhesion within the battery system.