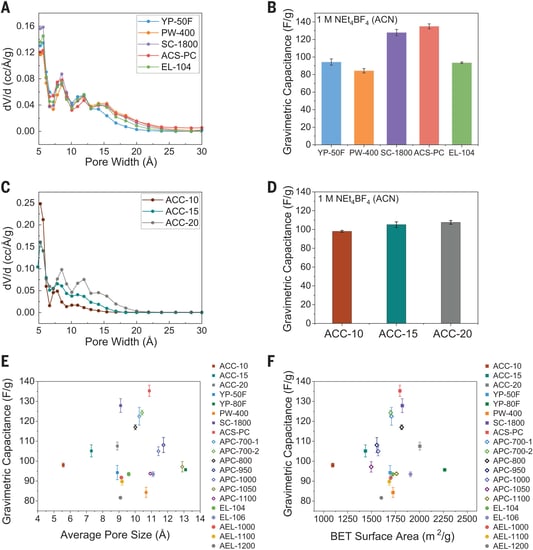

IntroductionCarbon black, a material derived from the incomplete combustion of hydrocarbons, has numerous applications in industries such as automotive, construction, and electronics. One question that arises in relation to carbon black is whether it is thermally conductive. In this article, we will explore the properties of carbon black and investigate its thermal conductivity.What is Carbon Black?Carbon black is a fine powder made up of elemental carbon that is produced by the combustion of petroleum products or natural gas. It has a high surface area and is used in a wide range of applications including rubber additives, pigments, and conductive plastics.Thermal Conductivity of Carbon BlackCarbon black is known for its high conductivity, which includes both electrical conductivity and thermal conductivity. Its thermal conductivity varies depending on factors such as particle size, structure, and surface area. However, carbon black can be considered thermally conductive, with a reported thermal conductivity of around 1 W/mK.Factors Affecting Thermal ConductivityThe thermal conductivity of carbon black can be affected by several factors, including:Particle size: Finer particles tend to have higher thermal conductivityStructure: Graphitized carbon black has higher thermal conductivity than amorphous carbon blackSurface area: Higher surface area generally leads to higher thermal conductivityApplications of Carbon BlackThe high thermal conductivity of carbon black makes it a useful material in various industries. Some applications of carbon black that require thermal conductivity include:Thermal interface materials in electronicsThermal management in batteriesConductive additives in plasticsCarbon black-filled composites for increased thermal conductivityComparison with Other MaterialsThe thermal conductivity of carbon black is relatively low compared to some other materials. For instance, copper has a thermal conductivity of around 400 W/mK, while diamond has a thermal conductivity of over 2000 W/mK. However, carbon black is much more cost-effective than these materials, making it a popular choice in many applications.ConclusionIn conclusion, carbon black can be considered thermally conductive, with a reported thermal conductivity of around 1 W/mK. Its thermal conductivity is affected by factors such as particle size, structure, and surface area. Carbon black is used in various industries for applications that require thermal conductivity, and although its thermal conductivity is relatively low compared to some other materials, it is a cost-effective and versatile choice.ReferencesCarbon Black Handbook, edited by J. B. Donnet, M. J. Wang, R. C. Bansal, and M. D. Strobl"Carbon Black as a Conductive Filler in Adhesives and Sealants," by Scott Armentrout, Adhesive and Sealant Council, 2002 Annual ConventionQuote InquiryContact Us Now!