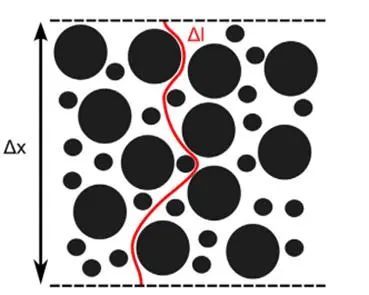

backdropThe driving range has always been the main bottleneck restricting the development of new energy vehicles, which depends on the energy density of the battery. The energy density of the battery is basically determined by the material system of the positive and negative electrodes. At present, the lithium battery has undergone multiple iterations, and the main upgrade is the positive electrode material. The power battery bms has been upgraded from the initial lithium iron phosphate to 523 and 622 (three numbers represent the proportion of nickel, cobalt and manganese) in the ternary lithium battery, and then to the present 811, which is the high nickel ternary. It is expected to be further upgraded to lithium-rich manganese based materials in the future. The negative electrode material did not achieve a good breakthrough, mainly from graphite to silicon carbon negative electrode. The upper limit of the energy density of the silicon carbon negative electrode is 400Wh/kg, and if the metal lithium is directly used as the negative electrode, the energy density is expected to reach 2600-3500Wh/kg, achieving a qualitative leap. However, the lithium metal negative electrode cannot be used with the traditional liquid electrolyte, because in the process of lithium ion charging and discharging, the liquid electrolyte is easy to form lithium dendrites, and these small crystal spikes will puncture the middle diaphragm, resulting in a short circuit of the positive and negative electrodes, which will cause the rapid rise in the temperature of the battery pack and lead to spontaneous combustion. That is to say, although lithium metal is currently the theoretical energy density of the highest negative electrode material, but limited to the safety of liquid electrolyte, it cannot be applied, and if you want to use lithium metal, you need a solid electrolyte, its conductive properties and liquid electrolyte are roughly the same, but can resist the formation of lithium dendrites, so as to achieve a substantial increase in battery energy density. This is an important reason why solid-state batteries have become mainstream. Similarly, for safety reasons, the operating voltage of the electrolyte can only be maintained at about 4.2V, which also limits the further expansion of the positive electrode material, and if the solid electrolyte is used, then the more extreme and higher energy density of the positive electrode system can be applied.The biggest difference between solid-state batteries and existing lithium batteries is that the diaphragm of solid-state batteries will be canceled, and the electrolyte will be changed from liquid to solid. In addition to the two most important advantages of safety and energy density, solid batteries have also been greatly improved in terms of automotive lightweight, cycle life, charging speed and operating temperature range. In terms of safety and energy density, the solid electrolyte completely solves the risk of spontaneous combustion of the liquid electrolyte, and after the application of the positive and negative electrode materials that are not compatible with the liquid electrolyte and have higher performance, the battery energy density is expected to break through the 500Wh/kg threshold, and then make the electric vehicle driving range of more than 1000 kilometers. In terms of automotive lightweight, the diaphragm and electrolyte together account for nearly 40% of the volume and 25% of the mass of the battery, and after they are replaced by solid electrolytes, the thickness of the battery can be greatly reduced, and after the safety is improved, the temperature control components inside the battery can be omitted, and the volume utilization rate can be further improved. In terms of cycle life, due to overcoming the lithium dendrite phenomenon, the cycle performance of solid-state batteries can reach about 45,000 times in an ideal state. In addition, the solid-state battery only takes ten minutes to fully charge, and the operating temperature range is expanded to more than three times. Semi-solid batteries are the transition routeHowever, solid-state batteries still have problems such as poor performance due to low ionic conductivity and high cost, so they are 5-10 years away from mass production. Solid-state battery electrolyte and electrode is a solid-state interface, it is difficult to form as close and sufficient contact as solid-liquid interface, which is not conducive to the transmission of lithium ions between positive and negative electrodes, affecting the battery performance, and by adding part of the electrolyte inside the solid state battery can improve the interface contact resistance, so the future technological development of solid state battery adopts a gradual transformation strategy. That is, the electrolyte content is gradually reduced, and finally solid electrolyte is used. According to the solid-liquid ratio of the electrolyte, the solid-state battery can be divided into semi-solid, quasi-solid and all-solid three, and the proportion of solid electrolyte increases in turn. Based on high safety, high compatibility with existing production lines and good economy, semi-solid batteries have become the best choice for the transition from liquid batteries to all-solid-state batteries, and it is expected that large-scale production can be achieved before 2025.In fact, semi-solid batteries do not help much to improve energy density, and the short-term driving factor is mainly the improvement of safety, especially in the risk test for external impact, external heating, internal short circuit and other problems, solid-state batteries perform far better than liquid batteries. In addition, the semi-solid battery is highly compatible with the traditional soft-pack battery production line in production and manufacturing, mainly on the basis of the original process to increase the in-situ solid-state process to achieve rapid switching, so the semi-solid state has the conditions for rapid volume in the short term, which is also the main reason why the semi-solid battery can be assembled to so many models this year. Incremental investment opportunity ElectrolyteThe electrolyte is still used in the semi-solid battery, which is mainly composed of solute lithium salt, organic solvents and additives, of which the solute lithium salt largely determines the operating temperature and safety of the lithium battery. At present, the mainstream electrolyte with LiPF6 (lithium hexafluorophosphate) as lithium salt may produce gas at high temperatures, which cannot meet the requirements of fast charging, while LiFSI (difluorosulfonimide) has the advantages of high conductivity, high chemical stability and high thermal stability. The electrolyte with LiFSI as lithium salt can better meet the development needs of solid state batteries with high energy density and wide operating temperature, so it is considered to be the next generation of lithium salt that is most likely to replace LiPF6. However, due to the complex production process, low yield and high cost of LiFSI, it has not been directly used as a solute lithium salt, but as a solute additive and LiPF6 mixed to improve the performance of the existing electrolyte. In the future, as technological progress drives down its cost, LiFSI is expected to gradually replace LiPF6, taking Tesla's newly launched high energy density battery 4680 battery as an example, the addition ratio of LiFSI increased from 3% to 15%, which is 5 times that of ordinary three-way batteries.There are various synthetic routes for LiFSI, of which the core intermediate difluorosulfonimide requires the use of sulfoxide chloride as a chlorinating agent, so sulfoxide chloride is the core raw material for LiFSI production and will benefit from the growth of LiFSI demand. However, due to the influence of the national environmental two and one capital restriction policy, the production capacity planning of sulfoxide chloride will hardly increase significantly. If sulfoxide chloride is very scarce in the future, its production capacity planning will only tilt to a few head enterprises with mature technology and less pollution in the production process. Electrolyte additivesIn addition, the supply chain of the semi-solid battery and the existing liquid battery is very high, and the positive and negative electrode materials have not changed fundamentally, mainly for the electrolyte to increase the in-situ solid-state process, which is simply to ensure a good interface contact between the electrode and the electrolyte through liquid injection first, and then gelate the electrolyte through external heating and other ways. Thus solving the problem of poor contact between solid and solid interfaces. In situ solid-state process requires additional special electrolyte additives for this process, of which the lithium additives are LiTFSI (lithium trifluoromethylsulfonimide), so LiTFSI manufacturers directly benefit. Negative electrodeSince the semi-solid battery still contains liquid components, it is still not possible to directly use metal lithium as a negative electrode, which means that some additional processing is needed to improve the electrical performance of the overall battery, and the commonly used is the negative pre-lithium treatment. The function of negative electrode prelithium is to offset the irreversible lithium loss caused by the formation of SEI film by replenishing lithium on the electrode material, so as to improve the total capacity and energy density of the battery, and the domestic companies that have laid out prelithium technology mainly have Guoxun High-tech and Yiwei Lithium Energy. Solid electrolyteIn addition to the electrolyte and the negative electrode, for the solid state battery industry, the most critical point is the development of solid electrolytes, the current mainstream technology path there are three main, respectively, polymers, oxides and sulfides, of which polymers belong to organic electrolytes, the last two belong to inorganic electrolytes.The development time of the polymer is the earliest, the advantage is that it is easy to process, can be compatible with the production equipment and process of the existing electrolyte, and has good mechanical properties and is relatively soft. However, its electrical conductivity is low, and it needs to be heated to 60 degrees to work normally; At the same time, due to the relatively poor high pressure resistance and thermal stability of this material, it can not adapt to the positive electrode system with higher energy density, so it does not meet the iterative trend of positive and negative electrode materials. At present, polymers are mainly made into composite materials with oxides to improve the overall performance of batteries.Just said, the solid state battery due to solid contact leads to low conductivity, and the conductivity of sulfide is the closest to the liquid electrolyte in the three technical routes, and its overall material is relatively soft, so the contact with the negative electrode is better, but there are still big difficulties in the process. First of all, its own production involves more complex sintering methods, resulting in its yield is generally low; Secondly, because the sulfide is easy to react with water and oxygen in the air to produce hydrogen sulfide highly toxic gas, it is also necessary to strictly control the production, such as the production requires an inert gas atmosphere, but this will increase the cost, and to synthesize the sulfide electrolyte requires the use of lithium sulfide precursor, and the cost of lithium sulfide precursor is also very expensive. Therefore, the production cost of sulfide electrolytes is much higher than the other two reasons, although technically sulfide is the most promising solid electrolyte for mass production, but considering the cost problem, there is still a long way to go from the real commercialization.In terms of global layout, the research and development of solid-state batteries is mainly concentrated in five countries and regions of China, Japan, Korea, the United States and Europe. China mainly takes the oxide route; Both Japan and South Korea are developing sulfide systems with national efforts. At present, Toyota of Japan is the company with the largest number of sulfide all-solid-state battery patents in the world, while the representative companies of South Korea mainly include LG Chemical, Samsung and PoSCO. In the United States, startups are the mainstay, and several routes are being promoted at the same time. Among the mainstream startups, Ionic Materials is based on polymer Solid system, Solid Power is based on sulfide system, and Quantum Scape is based on oxide system. Europe is the first region to promote the industrialization of polymer solid-state batteries, but based on the disadvantages of the above polymers, the final polymer did not form a trend, and now Europe has turned to investment, Volkswagen, BMW and Mercedes-Benz and other famous automakers have invested in the United States solid-state battery-related companies.Encapsulation mode BinderIn terms of process system, the adjustment of semi-solid batteries to the entire production line is relatively small, while the change of all-solid batteries will be relatively large, and one of the largest iterative direction is dry electrode technology. Unlike the traditional wet process used in lithium battery manufacturing, the dry electrode technology does not use solvents, and directly binds a small amount of PTFE binder and conductive agent to the positive and negative electrode powder, forming a thin electrode material strip through an extruder, and then laminates the electrode material strip onto the metal foil collector fluid to form the finished electrode.This technology is more suitable for the iterative trend of the next generation material system. For the negative electrode, because there is no need to add solvent and do not worry about the reaction between lithium metal and it, the pre-replenishment lithium technology can be implemented smoothly; For the positive electrode, it is easier to use higher energy density positive electrode materials such as ultra-high nickel. At the same time, because the solid binder PTFE used in dry electrode technology has elasticity, it can effectively solve the problem of separation from the electrode sheet caused by the expansion of the silicon-based negative electrode, and the cycle life will be several times increased. In terms of cost, compared with the wet process, the dry process completely skips the step of adding the solution, thus eliminating the complicated coating and pole sheet links, reducing the manufacturing cost, and also has a cost advantage in the input of drying equipment and the floor area of the factory.Dry electrode technology has been used in the all-solid state production mode announced by Samsung, and recently Tesla has made a breakthrough in this technology, the United States Patent and Trademark Office granted Tesla four patents in the field of battery dry electrode, 4680 battery also adopted this technology, and its cost advantage is expected to lay the foundation for the mass production of subsequent 4680 batteries. Since PTFE binders are critical to dry cell technology, producers of PTFE binders are expected to benefit.