Slurry preparation process challenges

(1) Water-based positive slurry. NMP is the only solvent for positive PVDF adhesives. NMP is toxic and carcinogenic, consumes more energy than water by evaporation, and requires solvent recovery systems in industrial applications. Therefore, it is urgent to develop the positive slurry of water system.

(2) Continuously stir. Coating is a continuous process, but the traditional mixing process is an intermittent process. The continuous mixing process reduces process time and energy consumption and improves process control, resulting in a more consistent slurry.

(3) Increase solid content. The solid content of the negative slurry is usually ~ 50%, and the positive NMP slurry is generally ~ 70%. If solid content can be increased while maintaining the processing properties of the coating process, material and energy costs will be reduced. The ultimate limit is the solvent-free coating process.

(4) Thicker electrodes. Thick electrodes reduce the amount of metal foil and diaphragm in the battery and increase the energy density. However, due to the longer electron and ion conduction pathways in the electrodes, thick electrodes will reduce the magnification performance of the battery. In addition, it is also difficult to produce thick coatings with good mechanical properties in industry.

(5) Synchronous double-sided coating. The coating drying oven is usually horizontal, and the wet coating is generally on the upper part of the metal foil. Current double-sided coating is done by drying one side before recoating the other side, which adds additional manufacturing time and passes the A-side coating through the oven twice. At the same time, double-sided coating requires a drying oven with a pole sheet floating.

(6) porosity gradient electrode. The two-layer electrode model calculated an optimal porosity of 10% near the fluid collector and 50% on the coated surface instead of a uniform 30%. In production, this requires a continuous double-layer coating or formwork technique.

Rheological challenge of electrode paste

The use of rheology as a predictive tool in the manufacturing process has three main challenges that need to be addressed:

(1) The differences between laboratory scale and industrial processes can be large, and the relationship between these amplification process changes and key properties (such as rheology) is unclear, it is necessary to use industry-relevant formulations, weight percentages and equipment (mixers and coators) in the study, and to characterize the rheology of the electrode paste. Rheology can detect subtle but important changes within a slurry batch during mixing and coating. For example, poor mixing can result in an uneven distribution of free carbon black in the slurry, resulting in changes in viscosity and viscoelasticity throughout the batch.

(2) Reveal the interactions between the components in the electrode slurry, what is their relationship to the formulation and mixing process? How do they affect flow characteristics?

(3) Quantitative understanding of optimal rheology in manufacturing and process control. Hydrodynamic modeling is a means of understanding coating flows and potential problems, such as unstable flows, stock buildup in dead zones, and defects such as pinholes, blisters, cracking, and delamination.

Electrode coating challenges

(1) Many of the limitations of current coating techniques are related to the use of liquid pastes. Usually in these slurries, 30%-60% of the mass is solvent, which needs to be removed from the electrode and leaves too much porosity in the dry electrode layer, so it needs to be calendered to be dense. In addition, higher water surface tension results in higher capillary forces during drying and poor collector wetting, resulting in cracking and delamination of the coating, especially for thick (>100 μm) electrodes. Dry or low-solvent electrode processes can avoid these problems, but also have their own challenges: ensuring adequate mixing of the dry powder, preparation of the dry powder mixture into a film of a specified width and thickness, and ensuring that the electrode film can adhere to the fluid collector.

(2) The electrode of the wet process has a spatially-uniform distribution of components and pore structure, and the optimal composition, thickness and porosity of the current electrode are obtained through repeated tests under the constraints of the slurry coating process. Relaxing these restrictions and providing greater flexibility could enable the design of higher performance electrodes.

(3) Optimization and control of electrode structure parameters. Electrode thickness is one of the key structural parameters that affect the energy density of lithium-ion batteries. Thicker slurry coated electrodes lead to slow transmission of lithium ions due to longer transmission path. Thick electrodes are also prone to cracking and delamination. Therefore, to increase electrode thickness, there are many challenges to overcome. Porosity is another key parameter that can have both positive and negative effects on lithium-ion battery performance. Currently, electrode porosity is mainly controlled through the calendering process, and thicker electrodes require additional processes to control the necessary porosity to ensure good performance. Tortuosity, that is, the ratio of the actual length of the lithium ion transport path to the linear distance between the starting point and the end point, is a structural parameter describing the difficulty of lithium ion transport within the electrode. For electrodes with higher mass loads, the challenge is the need to develop new electrode structure strategies to achieve low electrode tortuosity by controlling the shape, size, and distribution of the electrode holes without sacrificing other electrode properties.

(4) The main challenge of the dry electrode process is to reduce the content of inactive materials to a level comparable to that of wet coating, while some processes involve degreasing steps and high temperature sintering, making the process more expensive and potentially difficult to scale up.

Electrode drying process challenges

(1) Create an efficient drying model that correlates dynamic measurements of drying conditions with the final characteristics of the electrode to enable a more controlled drying process. Examples include computational fluid dynamics models at the continuous level, convection heat and mass transfer models at the air-porous material interface, theoretical models of drying of two-component colloidal suspensions, and one-dimensional models of particle coatings including Brownian diffusion, sedimentation and evaporation.

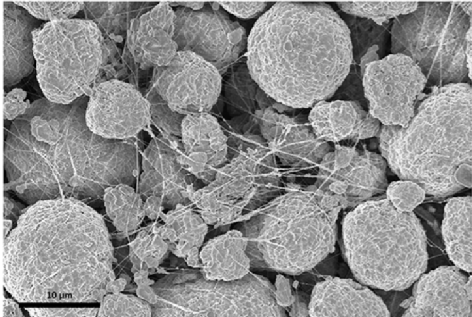

(2) The drying kinetics of the wet electrode film is particularly complex, and in order to better control the electrode structure and its corresponding electron and ion transport characteristics, we need to understand the process of electrode structure formation. Drying is the basis for forming the electrode structure, so it is necessary to develop advanced metrological tools to understand the physical processes that occur during drying, to measure and analyze the effect of solvent evaporation on defects, such as crack formation. The adhesive distribution can be characterized by energy spectrum EDX, Raman spectrum, Fourier transform infrared spectroscopy (FTIR) and multispot diffusion wave spectroscopy (MSDWS). Solvent evaporation can be measured by thermogravimetric analysis and quartz crystal microbalances (QCM). The surface temperature and drying stress during solvent evaporation can be measured by infrared (IR) thermography. Active materials can be characterized by SEM, X-ray CT, and fluorescent-based imaging/microscopy.

Electrode calender process challenges

During the calendering process, the particle structure of the active material (AM) and the carbon colloidal phase (CBD) are compressed and rearranged, and the intergranular porosity is reduced. The compaction of the pore structure of the electrode particles will in turn affect the electron ion transport performance and the battery performance.

(1) In the manufacturing process, the mechanical properties of the electrode are affected by the material composition, process parameters (such as roller temperature, speed) and electrode thickness. Due to the complex effects of these characteristics and parameters on the electrode rolling deformation, it is necessary to characterize the mechanical properties of the electrode, such as hardness, elastic deformation, and adhesion between the electrode and the collector. In order to obtain further understanding of the mechanism, a large number of systematic studies between parameters and material properties are needed, such as numerical simulation and experimental studies to obtain the dynamic mechanical response of calender to porous carbon gel phase.

(2) Capturing particle plastic deformation and fracture at high calendering levels is challenging, and a deeper understanding of interparticle forces is still needed to establish nonlinear constitutive behavior and study microstructure evolution within the electrode in high fidelity.