Unveiling the Secrets of Sodium-ion batteries: Disassembly and Analysis

Sodium-ion batteries have emerged as a promising alternative energy storage solution. This article delves into the meticulous process of disassembling sodium-ion batteries and inspecting their components.

Electrolyte Extraction and Analysis in Sodium-Ion Batteries

To extract the electrolyte from sodium-ion batteries, the discharge process is initiated at a constant current-constant voltage of 600mA until reaching 1.5V and current drops to 1mA. Then, under argon protection in a glove box, the battery's cover is removed. The cells of the sodium-ion batteries are secured for extraction with a special holder that features an auto-injection vial and placed in a centrifuge tube fit for centrifuge analysis.

The centrifuge starts at 4,000 rpm, reaching 10,000 rpm over 6 hours to extract the electrolyte from sodium-ion batteries successfully. Typically, around 3.4 grams of electrolyte is extracted, diluted with methylene chloride, and its composition analyzed using GC-MS. The key solvents extracted from the sodium-ion batteries include dimethyl carbonate (DMC), methyl ethyl carbonate (EMC), ethylene carbonate (EC), propylene carbonate (PC), and ethyl propionate (EP).

Conductive Salt Analysis in Sodium-Ion Batteries

A 200 μL sample of the electrolyte underwent ICP-OES examination for sodium salt content, revealing an average sodium concentration of 1.42 mol/L with NaPF6 as the primary conductive salt for sodium-ion batteries.

Detailed Solvent Composition with GC-FID

The relative solvent ratios of sodium-ion batteries' electrolyte were quantified via GC-FID analysis, showing an average composition of 41.8 wt% DMC, 15.2 wt% EMC, 14.3 wt% EP, 7.3 wt% EC, and 21.4 wt% PC.

Active Material Analysis in Sodium-Ion Batteries

Exploring the constituents of sodium-ion batteries, samples from electrodes were dissolved and analyzed through ICP-OES. An analysis of SEM-EDX further revealed the elemental distribution in sodium-ion batteries' electrodes.

Cathode Composition and Stoichiometry

The cathode in sodium-ion batteries was determined to be Ni/Mn/Fe in equal parts, leading to the composition Na0.96Ca0.02Nix0.33Mny0.33Fez0.33O2 layered oxide, while the anode remains hard carbon.

Pore Structure Analysis in Sodium-Ion Batteries

Investigating the pore structure of sodium-ion batteries, mercury intrusion assessment revealed the highest porosity in diaphragms at 40.6%, with specific pore sizes prevalent at 87.5 nm for diaphragms and larger sizes for electrodes.

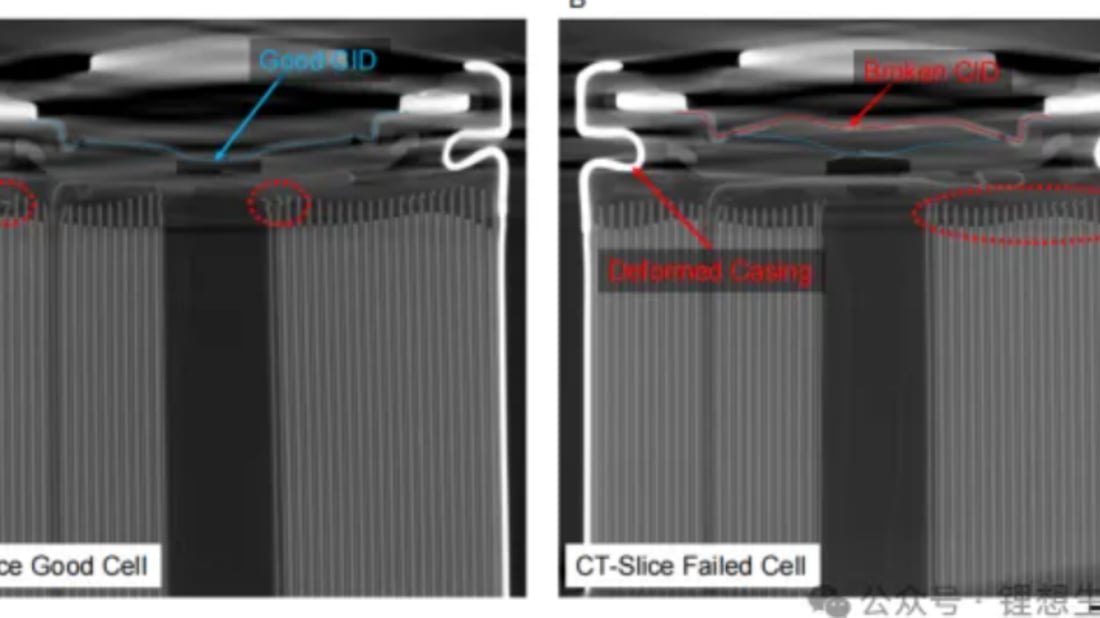

Imaging and Topography

The structural imaging from CT scans provided insights into the topography of the cathode and anode in sodium-ion batteries, contributing to a deeper understanding of their physical attributes and operational efficiency.