Rheology of the slurry: A Key Factor in Electrode Coating Processability

The rheology of the slurry plays a crucial role in processing lithium-ion battery electrodes. This slurry is a non-Newtonian fluid, showcasing pseudoplastic characteristics by decreasing viscosity under shear. The viscosity of the slurry is a critical determinant in the electrode coating processability, influencing coater pressure, speed, and slurry stability.

Slurry Dynamics and Viscosity

Understanding the rheology of the slurry highlights its nature as a shear-rate-dependent fluid. Unlike Newtonian fluids with consistent viscosity regardless of shear, non-Newtonian fluids like the slurry exhibit variable viscosity. Specifically, the slurry displays shear thinning; its viscosity decreases as shear rate increases.

Microscopic Mechanisms of Slurry Rheology

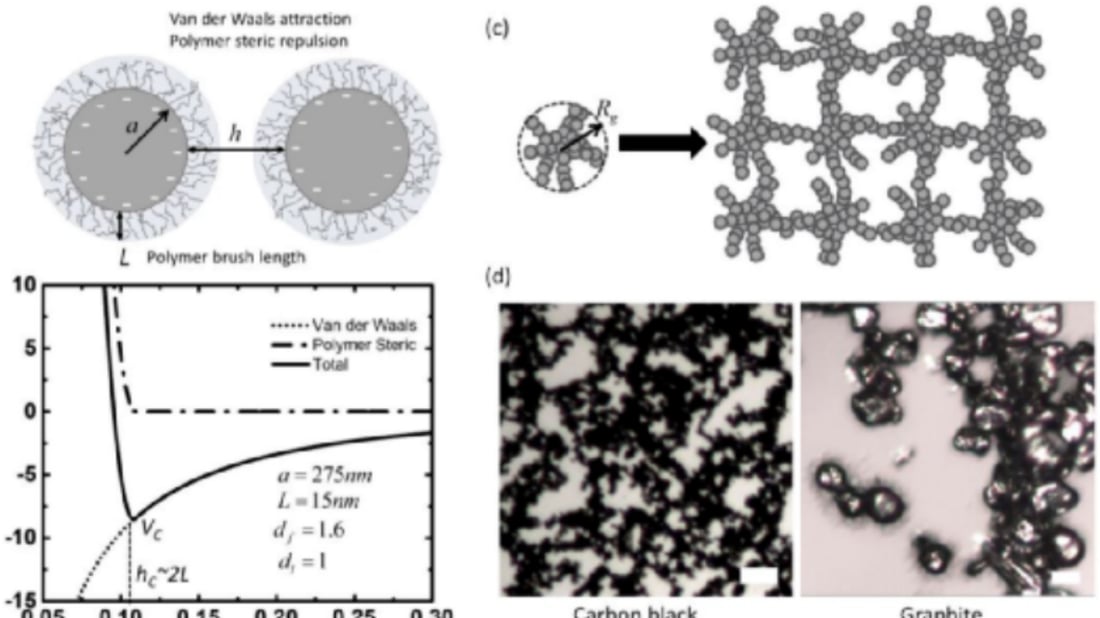

On a microscopic level, the rheology of the slurry hinges on interactions between its components. For example, in an anode slurry consisting of graphite, carbon black, PVDF binder, and NMP solvent, the particles' colloidal interactions dictate rheological behavior. These include van der Waals forces and steric hindrance from polymers, particularly between nanometer to micron-sized particles.

Impact on Electrode Coating

The link between rheology of the slurry and the coating process cannot be overstated. Slurries with higher viscosities encounter increased pressure and speed constraints during coating. Conversely, low-viscosity slurries risk spreading post-coating. The right balance involves controlling viscosity at the process's actual shear rate.

Particle Interactions and Slurry Structure

The rheology of the slurry is shaped by particle interactions, with carbon black and graphite interacting distinctly within the polymer suspension. At varying shear rates, carbon black networks break into smaller aggregates due to hydrodynamic forces, altering viscosity. This behavior is reversible with shear reduction rebuilding the network.

Polymer Influences in Slurry Rheology

The rheology of the slurry is also significantly impacted by polymer structures. The interaction between carbon black and PVDF, for example, varies with particle surfaces, affecting the layer thickness and inter-particle forces. In systems with graphite and CMC, adsorption levels, shear rates, and molecular weight all play key roles in viscosity changes.

Slurry Challenges with High-Nickel Materials

For high-nickel materials, the rheology of the slurry faced challenges with PVDF binders undergoing dehydrofluorination due to residual base groups. This results in an irreversible gel-like network which complicates viscosity management. Techniques to alleviate this issue by adding solvents may not successfully reduce viscosity.