The Role of Core Curvature in lithium battery mechanical stress

Introduction to Cylindrical Batteries in Modern Technology

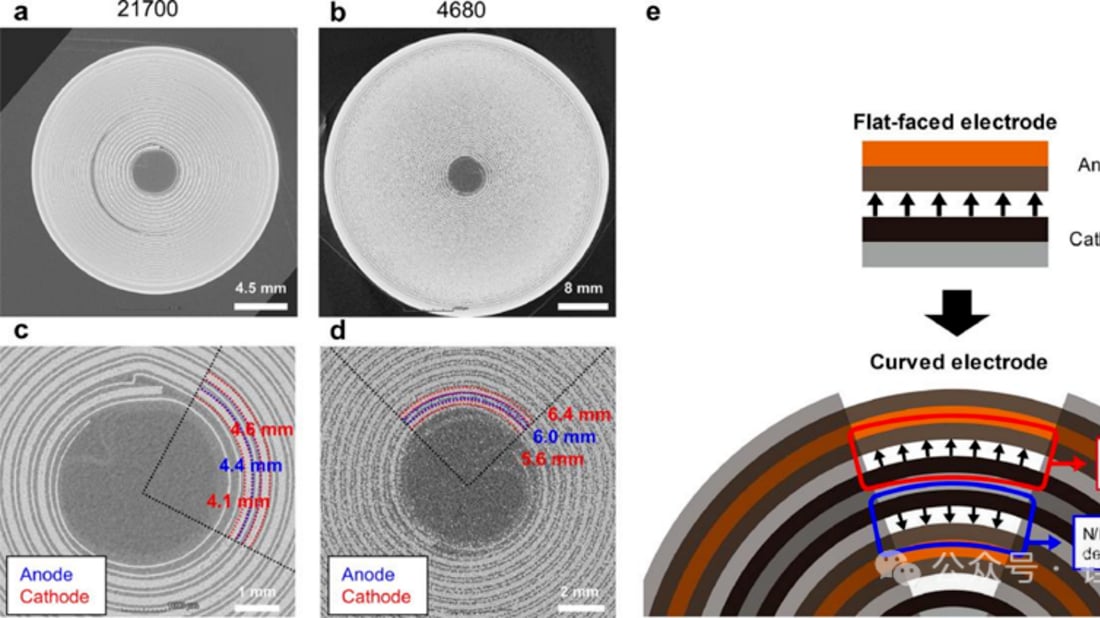

Cylindrical batteries are valuable in laptops and electric bicycles, praised for their thermal management, structural stability, and standardized production scalability. The advent of 4680 large cylindrical batteries has intensified interest in these products. A unique factor affecting their performance is the lithium battery mechanical stress.

Understanding Lithium Battery Mechanical Stress

Impact of Electrode Bending in Cylindrical Designs

When electrodes are wound during cylindrical battery production, inherent bending occurs, influencing mechanical and microstructural deterioration. This process impacts the lithium battery mechanical stress, varying with radial core position and altering the negative to positive capacity ratio (N/P ratio). Such variations cause local electrochemical performance changes, posing inconsistency risks and potential lithium metal deposition.

Curvature and Mechanical Load Effects

Both cylindrical and square batteries have curved core sections, with curvature indicating the departure from straightness at any point. Mechanical stress, particularly lithium battery mechanical stress, stems from curvature-induced bending and diffusion stress. The outer electrode surface, convex due to curvature, faces tensile stress while the inner concave surface experiences compression. During cycles, in-plane stress differences during electrode lithiation and delithiation are prominent, accentuating lithium battery mechanical stress.

Cyclic Stress and Fatigue in Lithium Battery Mechanical Stress

Consequences of Cyclic Fatigue Loads

The most critical challenge arises in the outer convex surface coating, where cyclic fatigue loads compound with tensile bending stress, involved in lithium battery mechanical stress. This cyclic loading can cause transverse microcracks and potentially local active layer cracking. Herein lies the vital impact of lithium battery mechanical stress.

Impedance Variations and Stress Sources

Purely geometric curvature-induced bending stress offers minimal impedance difference. However, impedance significantly rises when combined with lithium battery mechanical stress from cyclic fatigue during lithiation and delithiation. Therefore, recognizing the multifaceted nature of lithium battery mechanical stress is crucial.