Revolutionizing lithium battery Design with Generative AI Optimization

Introduction to Lithium Battery Advancements

As industries move towards achieving net zero carbon emissions, the reliance on lithium batteries becomes more profound, especially in sectors like electric vehicles and energy storage grids. The demand for specialized lithium battery designs is mounting as market requirements evolve.

The Significance of Electrode Microstructure in Lithium Battery Performance

The microstructure of electrodes plays a crucial role in lithium battery design. Sensitivity to manufacturing parameters such as tortuosity coefficients and active material (AM) volume affects energy output. Adjusting these factors can be achieved without reconfiguring existing production lines, making microstructural design an efficient pathway for lithium battery enhancement.

Generative AI: A Game-Changer in Lithium Battery Optimization

This study employs generative AI to map the link between manufacturing variables and electrode microstructure in lithium batteries. By bypassing costly physics-based simulations, AI methodologies offer optimized outcomes through comprehensive image-based data analysis.

Data-Driven Approaches for Lithium Battery Enhancement

Leveraging data-driven techniques, the research uses models trained on datasets from the Sandia National Laboratory. These innovative models predict microstructures beyond existing datasets, facilitating rapid lithium battery optimization through a Bayesian optimization loop.

Microstructural Indicators and Simulation Tools

Using pre-trained models, microstructures linked to varying manufacturing conditions are generated. Tools like TauFactor calculate vital microstructural indicators, which are then integrated into PyBaMM for lithium battery cell simulations. This process iteratively refines the manufacturing parameters for optimal lithium battery performance.

Experimental Insights and Lithium Battery Case Studies

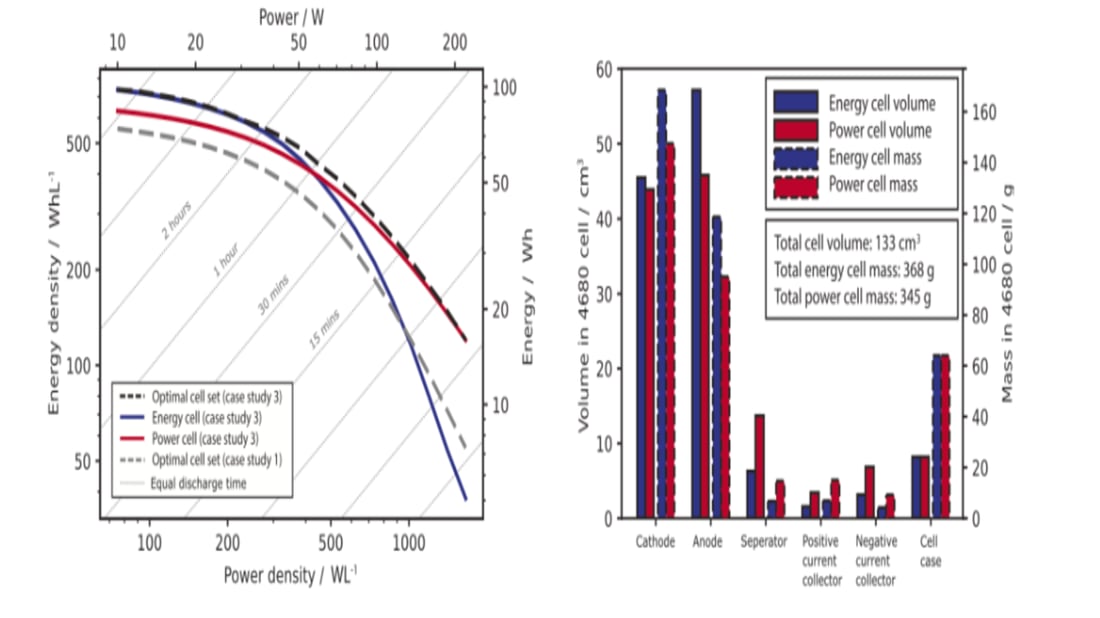

The study explores various optimization schemes within the lithium battery field. By focusing on key manufacturing parameters—such as active material percentage, porosity, and adhesive strength—valuable insights into optimizing lithium battery performance are gained.

Case Study on Enhanced Energy Density in Lithium Batteries

In a comprehensive case study, four parameters were optimized to maximize energy density within lithium batteries. The study found that tailored designs are essential, as different conditions require distinct manufacturing parameters for peak lithium battery performance.

Innovative Applications and Future Prospects

The modular nature of the optimization loop allows further explorations in the lithium battery domain. Future models could include a broader range of parameters, further enhancing the lithium battery design process, potentially including complex electrode gradients and different chemical compositions.

Conclusion: Unlocking New Potentials in Lithium Battery Design

Generative models hold transformative potential in lithium battery design, linking intricate manufacturing parameters with superior performance outcomes. By aligning optimization goals with real-world demands, the studies demonstrate substantial improvements in lithium battery configurations.