Lithium battery paste: An Essential Component in Battery Manufacturing

Introduction to Lithium Battery Paste and Its Importance

The lithium battery paste is pivotal to the manufacturing of lithium-ion batteries. It affects both the performance and quality of electrode pieces, directly influencing key attributes like voltage, energy density, cycle life, rate performance, and safety.

Key Characteristics of Quality Lithium Battery Paste

A top-notch lithium battery paste is defined by high solids content, even distribution, moderate viscosity, and finely dispersed particles. These traits ensure a uniform coating, enhance storage stability, and improve overall battery performance while maintaining safety.

Challenges in Lithium Battery Paste Manufacturing

Poor quality in lithium battery paste often stems from raw material issues, flawed preparation processes, and inadequate environmental controls. Impurities, uneven particle sizes, improper mixing, and environmental factors all contribute to undesirable outcomes like residual bubbles, affecting uniformity and stability.

Significance of Raw Material and Environmental Control

To produce superior lithium battery paste, manufacturers must select high-quality raw materials, optimize the preparation process, and ensure controlled environmental conditions. Addressing these aspects reduces risks and enhances the manufacturing process.

Innovative Solutions for Monitoring Lithium Battery Paste

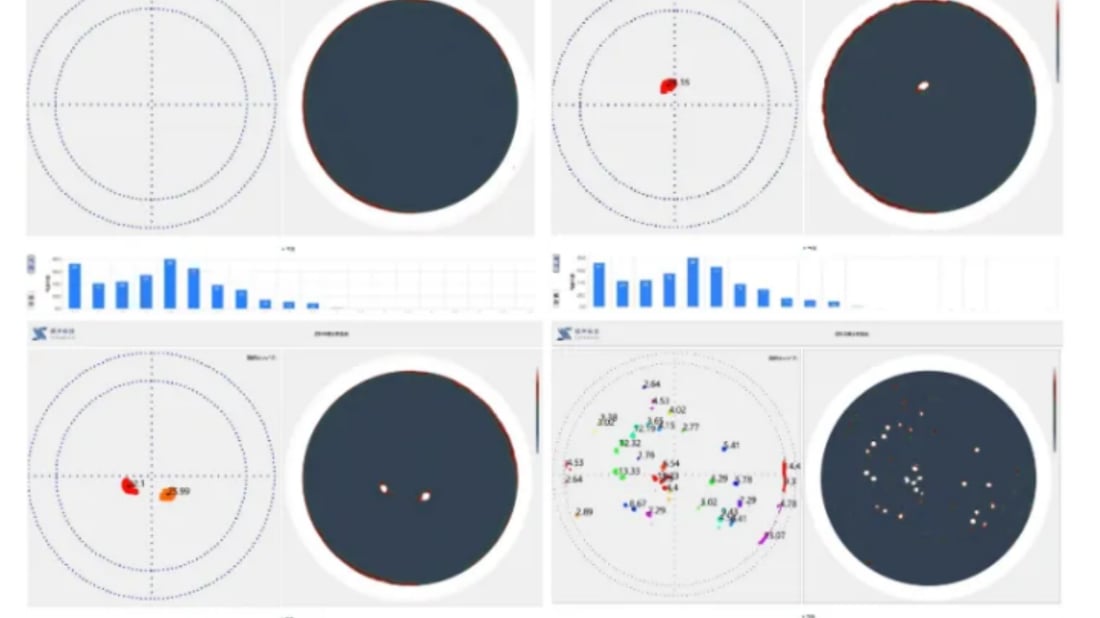

Lingsheng Technology introduces a cutting-edge ultrasonics-based solution for monitoring lithium battery paste quality in real-time. This system leverages non-invasive ultrasonic probes and advanced algorithms for detecting and managing anomalies like bubbles and agglomerates during the pulping stage.

Advantages of Real-Time Slurry Quality Monitoring

By setting parameter standards, this innovative system assesses the need for secondary deaeration of lithium battery paste. This process reduces scrap rates and refines the coating process, ensuring the delivery of high-quality batteries.