Is carbon black electrically conductive??

Carbon black is an amorphous form of carbon that is commonly used as a filler or pigment in various materials. Its unique properties make it an essential component in a majority of products that we use in our daily lives. One of the most common questions that people ask about carbon black is whether it is electrically conductive. In this article, we will explore the electrical conductivity of carbon black from different perspectives.

What is Carbon Black?

Carbon black is a finely divided powder that is produced by the incomplete combustion of carbonaceous materials such as oil, natural gas, or coal. It is composed of pure carbon in the form of elemental carbon and is characterized by its unique physical and chemical properties. Carbon black is commonly used in the manufacturing of rubber, plastic, ink, and other products due to its ability to impart desirable properties such as increased strength, durability, and UV resistance.

Conductive vs Insulating Materials

The electrical conductivity of a material depends on the ability of its electrons to move freely in response to an electric field. Conductive materials have free electrons that allow electric current to flow easily, whereas insulating materials have no free electrons and resist the flow of electric current. Carbon black is generally considered to be an insulating material, meaning it does not allow electric current to flow through it easily.

The Effect of Carbon Black Loading

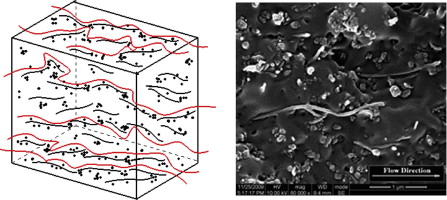

The electrical conductivity of a composite material that contains carbon black as a filler depends on the loading of carbon black in the composite. Increasing the loading of carbon black in a composite material can increase its electrical conductivity up to a certain point. However, beyond a certain loading threshold, the electrical conductivity may start to decrease due to the formation of agglomerates that inhibit the movement of electrons through the material.

The Role of Surface Modification

The surface modification of carbon black can significantly affect its electrical conductivity. Surface modifications such as coating or functionalization can improve the dispersion of carbon black in the composite material and reduce the formation of agglomerates. This, in turn, can improve the electrical conductivity of the composite material.

The Influence of Temperature

The electrical conductivity of carbon black can also vary with temperature. At low temperatures, the electrical conductivity of carbon black may be lower due to the lack of thermal energy to excite the electrons and promote their movement. However, at higher temperatures, the conductivity of carbon black may increase due to the increased thermal energy that can free up more electrons and allow better electron mobility.

The Impact of Particle Size

The particle size of carbon black can also affect its electrical conductivity. Finer particles tend to have a higher surface area that allows more contact points for electron transfer. This, in turn, can improve the electrical conductivity of the composite material. However, smaller particles may also be more susceptible to agglomeration that can decrease the electrical conductivity of the composite material.

The Role of Carbon Black Grade

The electrical conductivity of carbon black can also vary depending on its grade. Different grades of carbon black may have different-sized particles, different surface areas, and varying degrees of purity. Therefore, the electrical conductivity of carbon black may be different for different grades, and it's vital to use the appropriate grade in the intended application to ensure optimal conductivity.

Careful Selection is Key

From all the above discussion, it is evident that the electrical conductivity of carbon black can be influenced by various factors. Therefore, careful selection of carbon black-based materials is crucial to ensure the optimal electrical conductivity in the final product. Proper understanding of the application requirements, material properties, and process parameters can help determine the appropriate carbon black loading, surface modification, particle size, and grade to achieve the desired electrical conductivity.

Conclusion

Carbon black is an essential component in various materials and products. While it is generally considered an insulating material, its electrical conductivity can be modified by several factors. The electrical conductivity of carbon black depends on its loading, surface modification, thermodynamics, particle size, and grade, among other variables. Therefore, careful selection of carbon black-based materials is necessary to achieve the desired electrical conductivity.