Exploring Double-layer coating technology in Lithium-Ion Battery Production

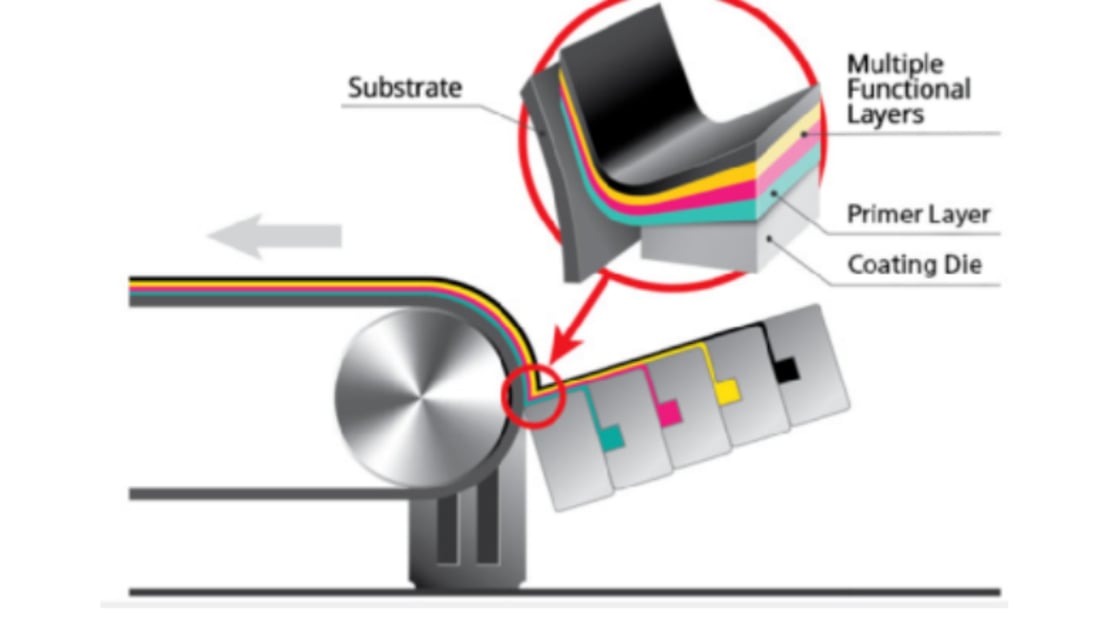

Introduction to Double-Layer Coating Technology

The innovative double-layer coating technology is reshaping the design of electrode pieces for lithium-ion batteries. This multi-layer architectural approach boosts performance, creating a "high-speed channel" for ions and electrons, thereby minimizing diffusion resistance and mitigating capacity loss. A key focus is the gradient distribution of electrode porosity, employing a high porosity upper layer and a dense lower layer to balance energy density and rapid charging capabilities.

Advancements in Double-Layer Coating Technology

Developed in tandem with the need to enhance production efficiency, the double-layer coating technology advances electrode performance by utilizing two distinct slurries. Examples of double-layer structure electrodes include:

- Binder Layering: To address adhesion issues caused by adhesive migration during coating drying, the lower slurry in the double-layer coating may be enriched with a high ratio of SBR.

- Conductive Agent Hierarchy: Maintaining equal total conductive agent content, studies reveal better battery performance with higher conductive agent concentration near the current collector.

- Particle Stratification: Differentiation in particle types and sizes allows dual energy density and power characteristics within the same battery design.

- Porosity Layers: Gradual porosity in the electrode's double-layer structure enhances lithium ion migration, boosting electrochemical performance at elevated current densities.

Challenges and Solutions in Double-Layer Coating Technology

The double-layer coating technology faces several challenges, such as a narrower process window compared to single-layer applications. Major issues include air entrainment, slurry mixing, and coating stability affected by viscosity and surface tension differences. Optimizing these parameters is crucial for achieving high-quality double-layer coatings.

Experimental findings (e.g., Figures 9, 10, 11, 12) demonstrate that the ultimate coating thickness achievable with double-layer coating technology surpasses single-layer applications, though with limitations in speed stability. Adjustments in flow ratio, viscosity, and tension are critical for successfully navigating the process window.

Future Prospects of Double-Layer Coating Technology

Despite limited studies, the advantages of double-layer coating technology in lithium-ion battery production are apparent. For optimal outcomes, meticulous control over slurry properties and process parameters is essential for a stable and uniform double-layer coating.

Conclusion

The implementation of double-layer coating technology is crucial for advancing lithium-ion battery efficiency. By leveraging intricate multi-layer structures, this approach offers superior battery performance and high-speed charging capabilities.