Impact of Internal Porosity of the Carbon Colloidal Phase on Lithium-Ion Battery Performance

Components of Lithium-Ion Battery Electrode Coating

The electrode coating in lithium-ion batteries consists of key elements: (1) active material particles facilitating lithium ion exchange during electrochemical processes; (2) the carbon colloidal phase, where conductive agents blend with polymer binders creating a three-dimensional conductive network essential for electron transportation; (3) interconnected microscopic pore spaces filled with electrolyte, which primarily function as channels for lithium ion movement within the battery electrodes.

Microstructure Characteristics of the Carbon Colloidal Phase

The internal porosity of the carbon colloidal phase is pivotal to the electrode coating structure in lithium-ion batteries, facilitating lithium-ion transport within electrolyte-filled pores. Diverse pores exist: micron-scale pores between active materials and nano-submicron pores within the conductive agent and binder mix. The carbon colloidal phase features specific internal porosity, influencing overall battery efficiency and performance.

Significance of Proper Dispersion Processes

Optimizing battery functionality necessitates controlling the internal porosity of the carbon colloidal phase through precise dispersion methods. Appropriate dispersion ensures balanced particle size and connectivity, maintaining effective electron transport networks and ion channels. High-strength shear mixing equipment is vital for achieving an optimal distribution, where careful control of dispersion prevents excessive breakdown, affecting network integrity.

Measurement of Internal Porosity

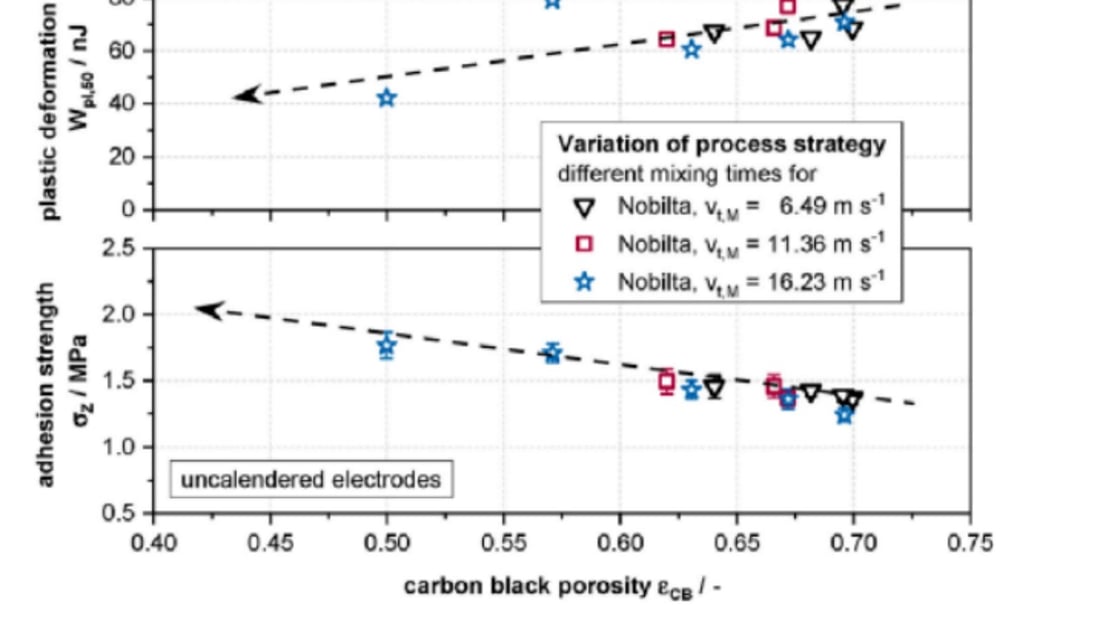

The internal porosity of the carbon colloidal phase dictates critical mechanical and electrochemical properties in electrodes. Methods such as high-speed shear dispersion calibrate this porosity by controlling energy input and dispersion levels, crucial for producing durable and efficient electrodes. Proper control can enhance conductivity while excessively dispersed phases risk elevating resistance, affecting battery performance.

The Role of Internal Porosity in Mechanical and Electrochemical Properties

By manipulating the internal porosity of the carbon colloidal phase, significant improvements in battery mechanics and performance are achievable. As internal porosity decreases, bonding strength and resistance improve up to an optimal threshold. Beyond this, excessive dispersion negatively impacts the long-range conductive network integrity. Therefore, mastering the internal porosity of the carbon colloidal phase through precise dispersion remains vital for optimizing lithium-ion battery performance.

Conclusion

In conclusion, the internal porosity of the carbon colloidal phase is a critical factor in lithium-ion batteries, affecting electron transport and lithium-ion movement within electrodes. Thorough understanding and application of dispersion techniques are essential for optimizing battery performance, highlighting the need for ongoing research in conductive agent design and utilization technologies.