Understanding Battery Lithium Ion 48V Slurry Dispersion

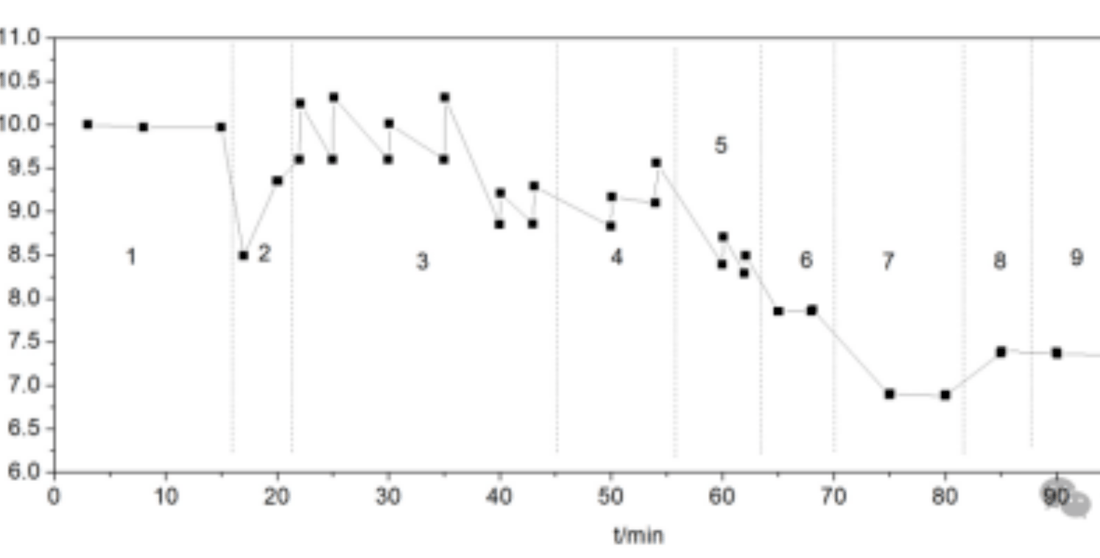

The dispersion degree of battery lithium ion 48V slurry is crucial for its production quality. It directly impacts viscosity and rheological characteristics, affecting the mechanical resistance during stirring. When the battery lithium ion 48V slurry is properly dispersed, particle agglomeration is minimized, reducing viscosity and consequently, the load on the stirring motor (current and power decrease). Conversely, poor dispersion results in higher viscosity, requiring the motor to exert more torque, leading to increased current and power. Monitoring these electrical parameters in real-time allows for establishing a model relating them to the battery lithium ion 48V slurry dispersion.

Battery Lithium Ion 48V Slurry Monitoring System Design

Sensor Configuration

Data acquisition for battery lithium ion 48V slurry dispersion involves:

- Current Sensor: Hall effect sensors like LEM LAH 50-P (0-50A, ± 0.5% accuracy).

- Voltage Sensor: Isolated voltage transmitters (e.g., VSM 025A, 0-600V range).

- Power Calculation: Real-time monitoring through current and voltage integration.

- Signal Processing: Data acquisition cards such as NI USB-6009 (16-bit resolution, 1kHz sampling rate) and low-pass filter with a 100Hz cutoff.

Feature Extraction and Modeling

Gather dynamic features for battery lithium ion 48V slurry:

- Time Domain: Analyze mean current, power fluctuation variance, and peak current ratio.

- Frequency Domain: Use FFT spectrum analysis to extract main frequencies and harmonics.

Develop models by:

- Experimental calibration comparing electrical parameters at varying dispersion levels, verified by microscopes or particle size analyzers.

- Machine Learning: Implement models such as random forest or SVM, using features like current mean and power variance to predict dispersion scoring (0-100%).

Real-Time Monitoring

Utilize computing devices like Raspberry Pi 4B running predictive models for real-time battery lithium ion 48V dispersion monitoring, displaying trends via HMI and triggering alarms if thresholds are exceeded.

Battery Lithium Ion 48V Application Examples

Optimizing Mixing Speed

Determine optimal mixing speeds by analyzing battery lithium ion 48V power calculations. Align mixing speed with power demands to enhance energy efficiency and avoid overloading. Employ closed-loop power speed control using PID algorithms to adjust motor speeds dynamically.

Monitoring Load Situations

Real-time power monitoring can identify excessive loads on battery lithium ion 48V mixers. Abnormal power signals hint at equipment faults. Through multidimensional threshold alarms and historical data mapping, detect and diagnose faults promptly to ensure stable operations.

Optimizing Mixing Formula and Process

Power calculations help determine optimal mixing ratios and process settings for battery lithium ion 48V slurry. Solid content variations change slurry rheological properties, impacting power needs. Adaptive power formula adjustments and cross-validation via online sensors ensure consistency in mixing formulations.