Ensuring Safety in Lithium-Ion Battery Production: Controlling Foreign Matter

Introduction to Lithium-Ion Battery Production Issues

In the production of lithium-ion batteries, controlling foreign particles is crucial. Particles like metal residues on polarizers, defects on diaphragms, and dust introduced during assembly can all lead to micro short circuits, affecting the battery's integrity.

Mechanisms of Short Circuit in Lithium-Ion Batteries

Two main principles govern how metal foreign objects cause short circuits in lithium-ion batteries. The first involves large metal particles piercing the diaphragm, resulting in a physical short circuit. The second involves metal objects in the positive electrode that dissolve and diffuse, forming a chemical dissolution short circuit.

Common Metal Contaminants in Lithium-Ion Batteries

Common contaminants found in lithium-ion battery production sites include metals like Fe, Cu, Zn, Al, Sn, and stainless steel, leading to potential internal short circuits.

Process-Induced Foreign Matter in Lithium-Ion Battery Production

The production process of lithium-ion batteries includes several stages where metal impurities can be introduced, like electrode slurry mixing, cutting processes, and welding, which all contribute to foreign matter presence.

Quality Control Standards in Lithium-Ion Battery Production

Lithium-ion battery manufacturers often impose strict controls on burr sizes, ensuring they remain below a set fraction of the diaphragm thickness to prevent short circuits.

Inspection and Testing in Lithium-Ion Battery Production

The batteries undergo various tests such as voltage withstand tests, X-ray detection, and aging tests to identify internal short circuits and ensure that lithium-ion batteries meet safety standards.

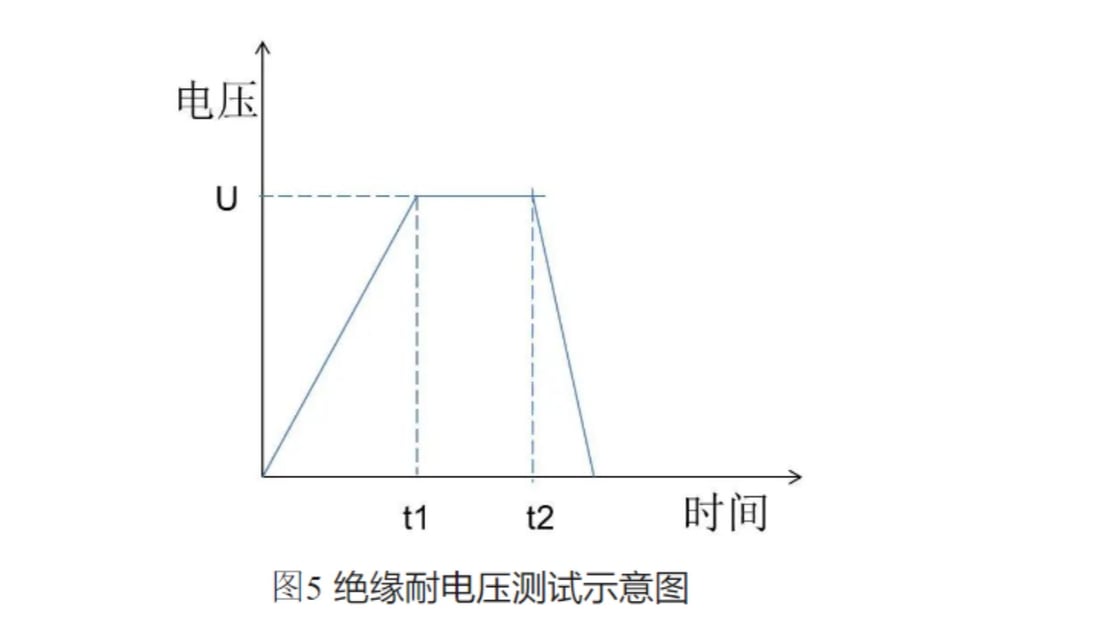

Voltage Endurance Tests

These tests are crucial for detecting metal foreign objects in lithium-ion batteries, as they help ensure that current remains within the specified range, indicating no short circuit.

Addressing Internal Micro Short Circuits in Lithium-Ion Batteries

Metal contaminants can cause lithium-ion batteries to self-discharge and suffer voltage drops. The aging process helps in identifying these issues by comparing voltage before and after storage and exposure to specific temperatures.

Challenges in Detecting Foreign Matter in Lithium-Ion Battery Production

The testing process for foreign matter, although necessary, is time-intensive and requires considerable resources. Ensuring thorough cleanliness control in workshops can significantly enhance the safety and quality of lithium-ion batteries.