Analysis of Internal Short Circuits in Lithium-ion Batteries

The intricate nature of the charging and discharging processes in real-world conditions brings challenges to Lithium-ion batteries are short-circuited internally. Even though battery energy management systems strive for optimal operation, mechanical, electrical, and thermal abuses can occur due to overcharging, overdischarging, and overheating, swiftly degrading battery performance. Eventually, Lithium-ion batteries are short-circuited internally, leading to the significant safety issue of thermal runaway. This article systematically explores internal short circuit principles, induced experimental methods, identification approaches, and preventive measures, serving as a guide for identifying and averting internal short circuits in lithium-ion batteries to enhance their safety and efficacy.

1. Mechanism of Internal Short Circuits in Lithium-ion Batteries

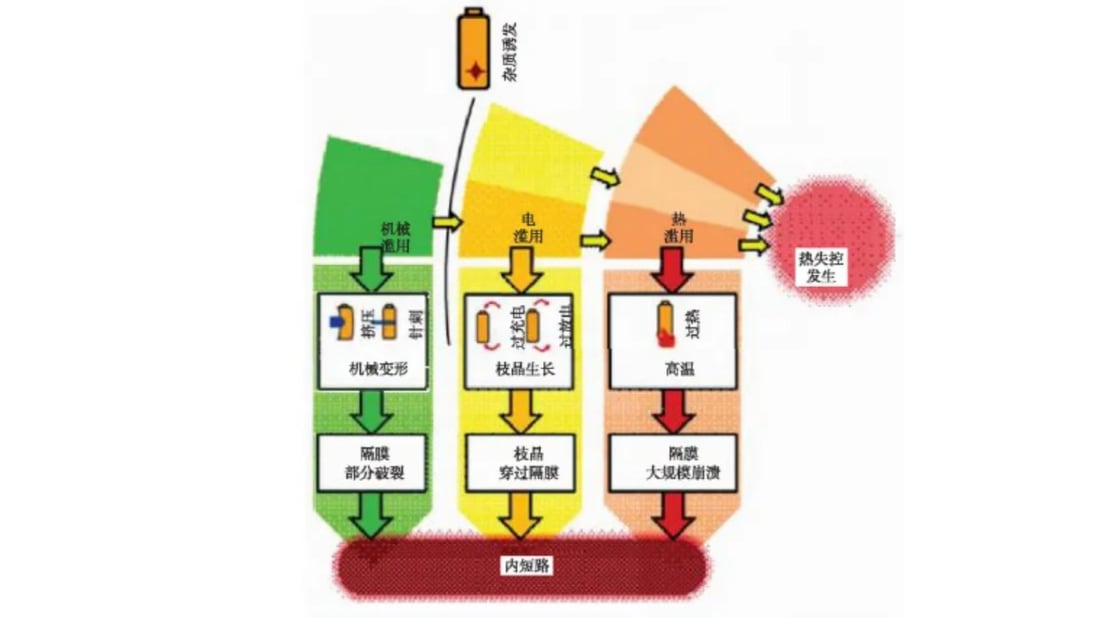

Internal short circuits in Lithium-ion batteries are short-circuited internally can be triggered under three conditions: mechanical, electrical, and thermal. Mechanical abuse causes deformation and ruptures within the battery through puncture or compression, whereas electrical abuse results in lithium precipitation and dendrite growth that connect the electrodes. High temperatures can cause thermal abuse, leading to separator collapse and short circuits. The occurrence of an internal short circuit generates a large current and localized heat that can culminate in thermal runaway, especially throughout the battery’s lifecycle.

Stages of Internal Short Circuit Development

When Lithium-ion batteries are short-circuited internally, the development can be divided into initial, middle, and terminal stages. Initially, voltage drops slowly with minimal heat dissipation, often going unnoticed for extended periods. The middle stage sees significant voltage drops with accumulated heat, raising the battery temperature. Finally, the terminal stage results in voltage dropping to 0V due to massive short circuits, leading to rapid thermal runaway.

2. Methods to Induce Internal Short Circuits in Lithium-ion Batteries

The experimental induction of short circuits in Lithium-ion batteries are short-circuited internally can be categorized into abuse condition methods, artificially designed internal defects, and equivalent resistance methods. Each method presents unique triggering mechanisms along with distinct advantages and disadvantages critical for research and development.

3. Identification Methods for Internal Short Circuits

Challenges and Techniques in Identifying Short Circuits

To prevent catastrophic thermal runaways when Lithium-ion batteries are short-circuited internally, several identification methods have been developed:

- Measured Data Deviation Identification: This technique involves comparing real-time voltage and temperature data against predictive models to identify deviations, though it has limitations in recognizing early-stage short circuits.

- Voltage Signal Anomaly Detection: This method identifies abnormal voltage fluctuations caused by specific battery type separators, limiting its application to those types alone.

- Battery Self-discharge Monitoring: Abnormal self-discharge rates can indicate internal short circuits, although this method can't be applied while the battery is operational.

- Consistency Monitoring of Battery Cells: By analyzing parameters that deviate from typical cell behavior, potential short circuits can be identified, albeit with challenges in parallel pack identification.

- Special Circuit Analysis: Monitoring voltage and current in symmetrical circuits for changes in symmetry helps pinpoint short circuits accurately, however, it demands high detection equipment costs.

4. Suppression Measures for Internal Short Circuits

Efforts to suppress Lithium-ion batteries are short-circuited internally involve two main aspects: battery materials and processes, and battery design and utilization strategies.

4.1 Battery Materials and Processes

Improving separators, electrolyte materials, and production processes are crucial. Using ceramic separators and flame-retardant electrolytes reduces short circuit risks. Enhanced coatings on electrodes help minimize heat and current surge during short circuits, further mitigating thermal runaway risks. Advanced impurity filtering processes and rigorous internal structural testing help prevent potential short circuits.

4.2 Battery Design and Utilization

Software strategies focus on real-time monitoring using Battery Management Systems (BMS) to preemptively detect and mitigate short circuit risks. Hardware designs incorporate fuse layering and advanced thermal systems to manage overheating effectively. Preheating measures prevent low-temperature-related dendrite growth, enhancing safety in working conditions where Lithium-ion batteries are short-circuited internally.