The lithium-ion battery is a secondary battery (rechargeable battery), which mainly relies on Li+ to insert and uninsert between two electrodes. The lithium-ion battery is a secondary battery (rechargeable battery), which mainly relies on Li+ to insert and uninsert between two electrodes. With the continuous development of downstream industries such as new energy vehicles, the production scale of lithium-ion batteries is constantly expanding. This paper takes lithium cobaltate as an example to comprehensively explain the principle, formula and process flow of lithium-ion batteries, the performance and testing of lithium batteries, production precautions and design principles. With the continuous development of downstream industries such as new energy vehicles, the production scale of lithium-ion batteries is constantly expanding. This paper takes lithium cobaltate as an example to comprehensively explain the principle, formula and process flow of lithium-ion batteries, the performance and testing of lithium batteries, production precautions and design principles.

First, the principle, formula and process flow of lithium-ion batteries;

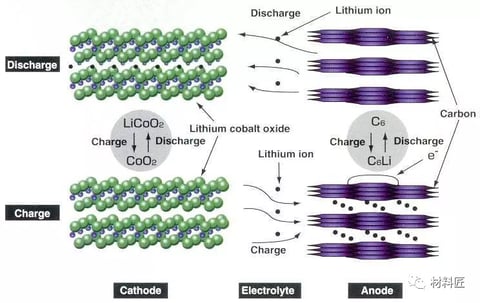

The working principle:

1. Positive electrode structure

LiCoO2 + conductive agent + Adhesive (PVDF) + Fluid collector (Aluminum foil)

2. Negative electrode structure

Graphite + conductor + thickener (CMC) + Binder (SBR) + fluid collector (copper foil)

3. Working principle

3.1 Charging Process

A power supply charges the battery, at this time the electron e on the positive electrode runs from the external circuit to the negative electrode, and the positive lithium ion Li+ "jumps" into the electrolyte from the positive electrode, "climbs" through the curved small hole on the diaphragm, and "swims" to the negative electrode, and the electrons that have run over are combined.

The reaction that occurs on the positive electrode is:

LiCo02->Li1-xCo02 + xLi++ xe

The reaction that occurs on the negative electrode is:

6C + xLi+ + xe->LixC6

3.2 Battery Discharge Process

Discharge has constant discharge and constant resistance discharge, constant discharge is actually in the external circuit to add a variable resistance that can change with the voltage change, the essence of constant resistance discharge is to add a resistance to the positive and negative terminals of the battery to allow electrons to pass. Thus, as long as the electrons on the negative electrode cannot travel from the negative electrode to the positive electrode, the battery will not discharge. Electrons and Li+ are acting at the same time, the same direction but the road is different, when discharging, electrons from the negative electrode through the electronic conductor to the positive electrode, lithium ion Li+ from the negative electrode "jump" into the electrolyte, "climb" the membrane on the curved small hole, "swim" to the positive electrode, and have long run over the electron together.

3.3 Charging and discharging characteristics

The positive electrode of the cell adopts LiCoO2, LiNiO2 and LiMn2O2, of which LiCoO2 is a crystal with a very stable layer structure, but when x Li ions are removed from LiCoO2, its structure may change, but whether it changes depends on the size of x.

It is found that when x >0.5, the structure of Li1-xCoO2 is extremely unstable, and crystalline collapse will occur, and its external performance is the overwhelming end of the battery cell. Therefore, the cell should control the x value in Li1-xCoO2 by limiting the charging voltage during use. Generally, the charging voltage is not greater than 4.2V, so x is less than 0.5, and the crystal shape of Li1-xCoO2 is still stable.

Negative C6 itself has its own characteristics, when the first formation, the Li in the positive LiCoO2 is charged to the negative C6, when the discharge Li back to the positive LiCoO2, but after the formation must have a part of Li to stay in the negative C6 center, to ensure that the next charge and discharge Li normal embedment, otherwise the cell overpower is very short, In order to ensure that a part of Li remains in the negative C6, it is generally achieved by limiting the lower discharge voltage: the upper safe charging voltage is less than 4.2V, and the lower discharge voltage is more than 2.5V.

The principle of the memory effect is crystallization, and this reaction hardly occurs in lithium batteries. However, the capacity of lithium-ion batteries will still decrease after multiple charging and discharging, and the reasons are complex and diverse. The main change is the positive and negative electrode material itself. From the molecular level, the hole structure containing lithium ions on the positive and negative electrodes will gradually collapse and block; From a chemical point of view, it is the active passivation of the positive and negative electrode materials, and the side reaction produces stable other compounds. Physically, the positive electrode material will gradually peel off, ultimately reducing the number of lithium ions in the battery that can freely move during the charge and discharge process.

Overcharging and excessive discharge will cause permanent damage to the positive and negative electrodes of the lithium-ion battery, from the molecular level, it can be intuitively understood that excessive discharge will lead to excessive release of lithium ions from the negative carbon and make its lamellae structure collapse, overcharging will force too many lithium ions into the negative carbon structure, and some of them can no longer be released.

Unsuitable temperatures will trigger other chemical reactions inside the lithium-ion battery to produce compounds we do not want to see, so there are protective temperature control membranes or electrolyte additives between the positive and negative electrodes of many lithium-ion batteries. When the battery temperature rises to a certain extent, the composite film hole closes or the electrolyte denatures, the internal resistance of the battery increases until the circuit is broken, and the battery no longer heats up to ensure that the battery charging temperature is normal.

Second, the formula and process of lithium battery

1. Positive and negative electrode formula

1.1 Positive electrode formula: LiCoO2+ conductive agent + adhesive + fluid collector (aluminum foil)

LiCoO2(10μm): 96.0%

Conductive agent (Carbon ECP) 2.0%

Adhesive (PVDF 761) 2.0%

NMP (Increased cohesiveness) : The weight ratio of the solid substance is 8:15

a) Positive viscosity control 6000cps (temperature 25℃);

b) The weight of NMP should be properly adjusted to meet the viscosity requirements;

c) Pay special attention to the influence of temperature and humidity on viscosity

Positive active material:

Lithium cobaltate: positive active substance, lithium ion source, lithium source for batteries. Non-polar substance, irregular shape, particle size D50 is generally 6-8 μm, water content ≤0.2%, usually alkaline, pH value is about 10-11.

Lithium manganate: non-polar substance, irregular shape, particle size D50 is generally 5-7μm, water content ≤0.2%, usually weakly alkaline, pH value is about 8.

Conductive agent: chain substance, water content < 1%, particle size is generally 1-5 μm. Superconducting Carbon black with excellent conductivity is usually used, such as Cochin Carbon Black Carbon ECP and ECP600JD, whose role is to improve the conductivity of the positive electrode material and compensate the electronic conductivity of the positive active material; The absorption of electrolyte of positive electrode plate is increased, the reaction interface is increased, and the polarization is reduced.

PVDF adhesive: non-polar substance, chain, molecular weight from 300,000 to 3,000,000; After water absorption, the molecular weight decreases and the viscosity becomes worse. Used to bind together lithium cobaltate, conductive agent and aluminum foil or aluminum mesh. Commonly used brands such as Kynar761.

NMP: Weakly polar liquid used to dissolve/swell PVDF while diluting slurry.

Fluid collector (positive lead) : Made of aluminum foil or aluminum strip.

1.2 Negative electrode formula: Graphite + conductor + thickener (CMC) + binder (SBR) + fluid collector (copper foil)

Anode material (graphite) : 94.5%

Conductive agent (Carbon ECP) : 1.0%(Cochin Superconducting Carbon Black)

Binder (SBR) : 2.25%(SBR = SBR rubber latex)

Thickener (CMC) : 2.25%(CMC = Sodium carboxymethyl cellulose)

Water: The weight ratio of solid matter is 1600:1417.5

a) Negative viscosity control 5000-6000cps (temperature 25 rotor 3)

b) The water weight needs to be properly adjusted to meet the viscosity requirements;

c) Pay special attention to the influence of temperature and humidity on viscosity

2, positive and negative mix

Graphite: negative active substance, constituting the main substance of the negative reaction; Mainly divided into natural graphite and artificial graphite two categories. Non-polar substances, easy to be polluted by non-polar substances, easy to disperse in non-polar substances; It is not easy to absorb water or disperse in water. Contaminated graphite, dispersed in water, is easy to reunite. General particle size D50 is about 20μm. The shape of the particles is varied and irregular, mainly spherical, flake, fibrous and so on.

Conductive agent: its role is:

a) Improve the conductivity of the negative electrode sheet and compensate the electronic conductivity of the negative active substance.

b) Improve the reaction depth and utilization rate.

c) Prevent the generation of dendrites.

d) The absorption capacity of conductive materials is used to improve the reaction interface and reduce polarization. (Can choose to add or not to add according to the graphite particle size distribution).

Additives: reduce irreversible reaction, improve adhesion, improve slurry viscosity, prevent slurry precipitation.

Thickener/antiprecipitation agent (CMC) : polymer compound, soluble in water and polar solvents.

Isopropyl alcohol: weakly polar substance, which can reduce the polarity of adhesive solution and improve the compatibility of graphite and adhesive solution after addition; Has a strong defoaming effect; Easy to catalyze the adhesive network crosslinking, improve the bond strength.

Ethanol: weakly polar substance, after addition can reduce the polarity of the adhesive solution, improve the compatibility of graphite and adhesive solution; Has a strong defoaming effect; It is easy to catalyse the linear cross-linking of the adhesive and improve the bond strength (the role of isopropyl alcohol and ethanol is essentially the same, and the cost factor can be considered in mass production and then choose which to add).

Water-based adhesive (SBR) : The bonding of graphite, conductive agent, additive and copper foil or copper mesh. Small molecule linear chain emulsion, highly soluble in water and polar solvents.

Deionized water (or distilled water) : diluent, added in appropriate amounts to change the fluidity of the slurry.

Negative lead: made of copper foil or nickel strip.

2.1 Positive mixing:

2.1.1 Pretreatment of raw materials

1) Lithium cobaltate: dehydration. Generally, it is baked for about 2 hours at 120 °C atmospheric pressure.

2) Conductive agent: dehydration. Generally, it is baked for about 2 hours at 200 °C atmospheric pressure.

3) Adhesive: dehydration. Generally, 120-140 °C atmospheric pressure baking for about 2 hours, the baking temperature depends on the size of the molecular weight.

4) NMP: Dehydration. Use dry molecular sieve for dehydration or special feeding facilities for direct use.

2.1.2 Ball milling of materials:

1) At the end of 4 hours, sieve and separate the ball mill;

2) Pour LiCoO2 and Carbon ECP into the bucket, add the grinding ball (dry material: grinding ball =1:1), and carry out ball grinding on the rolling bottle and the rotating speed is controlled above 60rmp

2.1.3 Blending of raw materials:

1) Dissolution of adhesive (according to standard concentration) and heat treatment.

2) lithium cobalt oxide and conductive agent ball milling: the powder is initially mixed, lithium cobalt oxide and conductive agent are bonded together, and the agglomeration effect and conductivity are improved. The slurry will not be distributed separately in the adhesive, and the ball milling time is generally about 2h; In order to avoid mixing impurities, agate balls are usually used as ball grinding mesons.

2.1.4 Dispersion and wetting of dry powder:

Principle: The solid powder is placed in the air, and over time, it will adsorb part of the air on the surface of the solid, after the liquid adhesive is added, the liquid and the gas begin to compete for the solid surface; If the solid and gas adsorption force is stronger than the liquid adsorption force, the liquid can not soak the solid; If the solid and liquid adsorption force is stronger than the gas adsorption force, the liquid can soak the solid and squeeze out the gas.

When the wetting Angle is less than 90°, the solid is soaked. When the wetting Angle is >90°, the solid is not soaked.

All members of the positive electrode material can be soaked by the adhesive solution, so the positive powder is relatively easy to disperse.

Impact of dispersion method on dispersion:

1) static method (long time, poor effect, but does not damage the original structure of the material);

2) Stirring method: rotation or rotation plus revolution (short time, good effect, but may damage the individual material's own structure).

The effect of mixing paddle on dispersion speed: mixing paddle roughly includes snake shape, butterfly shape, ball shape, paddle shape, gear shape, etc. The general serpentine, butterfly, and paddle type mixing paddle is used to deal with the initial stage of difficult to disperse materials or ingredients; Spherical, gear shape for low dispersion difficulty state, the effect is good.

Effect of stirring speed on dispersion speed. Generally speaking, the higher the mixing speed, the faster the dispersion speed, but the greater the damage to the material's own structure and the equipment.

Effect of concentration on dispersion rate. Under normal circumstances, the smaller the slurry concentration, the faster the dispersion speed, but too thin will lead to waste of materials and the increase of slurry precipitation.

Effect of concentration on bond strength. The greater the concentration, the greater the flexure strength and the greater the bonding strength. The lower the concentration, the smaller the bonding strength.

Effect of vacuum degree on dispersion velocity. The high vacuum is conducive to the gas discharge from the gap and surface of the material and reduces the difficulty of liquid adsorption. It will be much less difficult for materials to disperse evenly in the case of complete weightlessness or reduced gravity.

Effect of temperature on dispersion rate. At the appropriate temperature, the slurry fluidity is good and easy to disperse. Too hot slurry is easy to crust, too cold slurry fluidity will be greatly reduced.

Dilution: The stock is adjusted to a suitable concentration for easy coating.

2.1.5 Procedure

a) Pour NMP into the power mixer (100L) to 80°C, weigh PVDF and add it, and start; Parameter setting: speed 25±2r/min, stirring 115-125min;

b) Turn on the cooling system, add the grinding positive dry material four times on average, each interval of 28-32min, add NMP in the third feeding according to the material needs, and add NMP after the fourth feeding; Parameter setting of power mixer: speed is 20±2r/min

c) After the fourth feeding 30±2min, stir at high speed for 480±10min; Power mixer parameter setting: revolution is 30±2r/min, self-conversion is 25±2r/min;

d) Vacuum mixing: Connect the power mixer to the vacuum, keep the vacuum degree to -0.09Mpa, and stir for 30±2min; Parameter setting of power mixer: revolution is 10±2min, self-conversion is 8±2r/min

e) Take 250-300ml slurry and measure the viscosity with a viscometer; Test conditions: Rotor number 5, speed 12 or 30rpm, temperature range 25°C;

f) The positive electrode material is removed from the power mixer for colloid grinding and screening, and at the same time, the stainless steel basin is labeled, and the pulping equipment operator can flow into the pulping operation process after handover.

2.1.6 Precautions

a) Complete and clean the machine equipment and working environment;

b) When operating the machine, pay attention to safety to avoid head injury.

2.2 Negative electrode mixing

2.2.1 Pretreatment of raw materials:

1) Graphite:

A. Mix to homogenize raw materials and improve consistency.

B, 300~400°C atmospheric pressure baking, remove the surface oily substances, improve the compatibility with water-based adhesives, round the graphite surface edges (some materials in order to maintain surface characteristics, do not allow baking, otherwise the efficiency is reduced).

2) Water-based adhesive: appropriate dilution to improve dispersion.

2.2.2 Blending, wetting and dispersing:

1) The polarity of graphite and adhesive solution is different, and it is not easy to disperse.

2) The graphite can be initially wetted with alcohol aqueous solution and then mixed with adhesive solution.

3) The mixing concentration should be appropriately reduced to improve dispersion.

4) In order to reduce the distance between polar and non-polar substances and improve potential energy or surface energy, the dispersion process is an endothermic reaction, and the overall temperature decreases during agitation. If conditions permit, the stirring temperature should be appropriately increased to make heat absorption easy, while improving the fluidity and reducing the difficulty of dispersion.

5) Mixing process such as adding vacuum degassing process, remove gas, promote solid-liquid adsorption, the effect is better.

6) Dispersion principle, dispersion method and the relevant content of positive ingredients

2.2.3 Dilution:

Adjust the stock to a suitable concentration for easy coating.

2.2.4 Ball milling of materials

1) Add the negative electrode and KetjenblackECP into the bucket at the same time (dry material: grinding ball =1:1.2) for ball grinding on the rolling bottle and the rotating speed is controlled above 60rmp;

2) At the end of 4 hours, sieve and separate the ball mill;

2.2.5 Operations

1) The purified water is heated to 80°C and poured into the power mixer (2L)

2) Add CMC and stir for 60±2min; Power mixer parameter setting: revolution is 25±2min, self-conversion is 15±2r/min;

3) Add SBR and deionized water and stir for 60±2min;

Parameter setting of power mixer: revolution is 30±2min, self-conversion is 20±2r/min;

4) The negative dry material is added in an average sequence of four times, and pure water is added at the same time, each interval of 28-32min; Parameter setting of power mixer: revolution is 20±2r/min, self-conversion is 15±2r/min;

5) After the fourth feeding 30±2r/min, stir at high speed for 480±10min;

Power mixer parameter setting: revolution is 30±2r/min, self-conversion is 25±2r/min;

6) Vacuum mixing: Connect the power mixer to the vacuum, maintain the vacuum degree of -0.09 to 0.10Mpa, stir 30±2min;

Parameter setting of power mixer: revolution is 10±2min, self-conversion is 8±2r/min

7) Take 500ml of slurry and measure the viscosity with a viscometer;

Test conditions: Rotor number 5, speed 30rpm, temperature range 25°C;

8) Take the negative material out of the power mixer for abrasives and sieving, at the same time paste a mark on the stainless steel basin, and can flow into the pulping operation process after handing over to the pulping equipment operator.

2.2.6 Precautions

1) Finish, clean up the machine equipment and working environment;

2) When operating the machine, pay attention to safety to avoid hitting the head.

Ingredients note:

u prevent mixing with other impurities;

u Prevent slurry spatter;

The concentration (solid content) of the slurry should be gradually adjusted from high to low, so as not to increase the trouble;

u In the intermittent process of stirring, pay attention to scraping the edge and scraping the bottom to ensure uniform dispersion;

u The slurry should not be shelved for a long time to avoid precipitation or uniformity reduction;

u Materials to be baked must be sealed and cooled before they can be added to avoid changes in the properties of component materials;

The length of mixing time is mainly based on the equipment performance and the amount of material added;

The use of mixing paddle is replaced with the difficulty of slurry dispersion, and the speed can be adjusted from slow to fast if it cannot be replaced, so as not to damage the equipment;

u Screen the slurry before discharge to remove large particles to prevent band breakage during coating;

u To strengthen the training of ingredients personnel to ensure that they master professional knowledge, so as not to cause a disaster;

The key to the ingredients is to disperse evenly, master the center, other ways can be adjusted by themselves.

1. Parameters required for battery production

1. Pole size

2. Pulping process

a) Fluid collector size

Positive electrode (aluminum foil), intermittently coated

Negative electrode (copper foil), intermittently coated

b) pulping weight requirements

3, positive pulping after the following processes:

Cutting large pieces cutting small pieces weighing sheet (matching sheet) baking rolled sheet pole lug welding negative pulping after the following processes:

Cutting large pieces of small pieces weighing pieces (matching pieces) baking rolled sheet pole ear welding

4, rolling requirements

5. Matching scheme

6, pole baking

Note: The vacuum degree of the vacuum system is -0.095-0.10Mpa; The protective gas is high purity nitrogen, and the gas pressure is greater than 0.5Mpa

7, polar ear production

a) Positive electrode:

The positive ear uses ultrasonic welding at the positive plate. The end of the aluminum strip is flush with the edge of the pole piece.

b) Negative electrode:

Nickel strip size: 0.10×3.0×48mm, the nickel strip is directly spot-welded with the spot welding machine, requiring 8 spot welding points the right side of the nickel strip is aligned with the right side of the negative electrode, and the end of the nickel strip is flush with the edge of the pole.

8 Diaphragm size: 0.025×44.0×790±5mm

9 roll needle width: 22.65±0.05mm

10 Press core: After the battery is wound, first paste 24mm wide transparent adhesive paper on the bottom of the battery core, and then cold press twice with the press machine.

11 Requirements before inserting the battery into the shell

Adhesive paper 1:10.0 ×38.0±1.0mm, adhesive paper evenly distributed on both sides of the cell;

Adhesive paper 2:10.0×38.0±1.0mm, nickel strip in the center of adhesive paper;

Adhesive paper 3:24.0 ×30.0±2.0mm, adhesive paper evenly distributed on both sides of the cell;

The right side of the nickel strip is 7.0±1.0mm from the right side of the cell.

12 casing

When installing the shell, both hands should be used to exert force at the same time, slowly loading the battery cell into the battery shell, and it is forbidden to scratch the battery cell.

13 Negative ear welding

The negative nickel strip and the steel shell should be welded with a spot welding machine to ensure the welding strength and prohibit virtual welding.

14 Laser Welding

Laser welding should be carefully on the fixture, the battery shell and the top cover can be welded after a good match, pay attention to avoid welding bias.

15 Battery vacuum baking

Note:

(1) The vacuum degree of the vacuum system is -0.095~-0.10MPa;

(2) The protection gas is high purity nitrogen, and the gas pressure is > 0.5MPa;

(3) Vacuum once an hour and inject nitrogen once

16 Liquid injection volume: 2.9±0.1g

Relative humidity of the liquid injection room: ≤30%, temperature: 20±5℃ Sealing tape: 6mm wide red tape, adhesive paper, wipe the electrolyte at the liquid injection port, and fix the cotton at the liquid injection port with two rubber bands.

17 formation system

(1) Open forming process

a) Constant current charging: 40mA×4h; 80mA×6h

Voltage limit: 4.00V

b) The full test voltage, the voltage ≥3.90V battery to seal, voltage <3.90V battery with 60mA constant current to 3.90~4.00V after sealing, and then hit steel ball

c) Battery cleaning, cleaning agent is acetic acid + alcohol

(2) Continuous formation system

Sequential formation:

a) Constant current charging (400mA, 4.20V, 10min)

b) Hibernation (2min)

c) Constant current charging (400mA, 4.20V, 100min)

,

d) Constant voltage charging (4.20V, 20mA, 150min)

e) Hibernation (30min)

f) Constant current discharge (750mA, 2.75V, 80min)

g) Sleep (30min)

h) Constant current charging (750mA, 3.80V, 90min)

j) Constant voltage charging (3.80V, 20mA, 150min)

(3) Detection of capacitance

The battery capacity is divided according to the following grades:

Check the full voltage after the battery is placed in the cabinet, and the battery with a voltage < 3.77V is recharged by the program:

(1) Constant current charging (750mA, 3.80V, 10min)

(2) Sleep (2min)

(3) Constant current charging (750mA, 3.80V, 30min)

(4) Constant voltage charging (3.80V, 20mA, 60min)

18 Battery recheck

After the battery is divided into the lower cabinet, it is placed at room temperature for 20 days for reinspection. The steps are as follows:

a) Use a shaping machine to shape the battery;

b) Full test battery thickness, voltage, internal resistance, classification method is as follows:

Second, the battery production process

1, (positive and negative) dry mixing → wet mixing → rolling paste on conductive substrate → 3-step drying → winding → edge cutting (cut to a certain width) → roller press → winding (spare) dry mixing using ball milling, grinding ball is glass ball or zirconia ceramic ball;

Wet mixing. Planetary mixer, the blades are respectively installed on 2-3 axes, the mixing effect is better. The amount of solvent in the wet mix should be appropriate to form a suitable flow transformation to obtain a smooth coating. Roll-coated electrode paste to ensure a certain viscosity, the paste is coated on both sides of aluminum foil or copper foil, and the thickness of the coating depends on the battery model. The NMP (or water) evaporates from the coating with the flow of hot air or dry nitrogen, and the solvent can be recovered and reused. Rolling is to improve the density of the coating, and make the electrode thickness can meet the size of the battery assembly, the pressure of the rolling stage should be moderate, so as not to scatter the powder when winding.

2, battery assembly

Assembly process of cylindrical battery: insulation bottom ring into the cylinder → coil into the cylinder → Insert the mandrel → Weld the negative collector into the cylinder → Insert the insulation ring → cylinder rolling → vacuum drying → liquid injection → Combination cap (PTC components, etc.) welding to the positive lead → sealing → X-ray inspection → Numbering → formation → cycling → aging.

Square battery assembly process: insulation bottom into the steel box → sheet combination cell into the cylinder → negative collector plate welded to the steel box → upper sealing washer → Positive collector plate welded to the rod lead → Combination cover (PTC components, etc.) welded to the rotary lead → combination cover positioning → Laser welding → vacuum drying → liquid injection → Sealing → X-ray inspection → Numbering → formation → cycling → aging.

Assembly process description: Take cylindrical battery as an example (the basic process of square battery is the same). Before winding the core into the cylinder, the aluminum strip (0.08-0.15 ㎜ thick, 3㎜ wide) and the nickel strip (0.04-0.10 ㎜ thick, 3㎜ wide) are welded in the designated place of the positive and negative conductive matrix with ultrasonic waves as the collector electrode.

The battery diaphragm is generally composed of PE/PP2 layers or PP/PE/PP 3 layers, and the diaphragm is heat treated at 120 ° C to increase its deterrence and improve its safety.

The positive electrode, the diaphragm and the negative electrode 3 are folded into the cylinder after superposition, and because of the paste electrode, it is necessary to combine the paste material with the substrate well to form a high-density electrode, especially to prevent the powder from penetrating the diaphragm and causing a short circuit inside the battery.

Before the winding cell is inserted into the cylinder, an insulating bottom is placed into the bottom of the cylinder to prevent the internal short circuit of the battery. This is the same for ordinary batteries.

Electrolytes generally use LiPF6 and non-aqueous organic solvents, before the vacuum injection, the battery should be vacuum dried 24/h to remove the moisture and moisture in the battery components, so as to avoid the reaction of LiPF6 with water to form HF and shorten the life.

The battery seal adopts the process of applying sealant, inserting gasket, rolling edge and section shrinkage, and the basic principle is the same as that of alkaline rechargeable batteries. After sealing, the battery is removed with a mixture of isopropyl alcohol and water to remove oil dirt and spilled electrolyte, and then dried. Use an odor sensor or "sniffer" element to check for battery leakage.

After the entire battery assembly is completed, the battery should use X-rays to identify whether the internal structure of the battery is normal, and check whether the battery is not correct, the steel shell cracks, the solder joints, and the short circuit, etc., to exclude the batteries with the above defects and ensure the quality of the battery.

The last process is the formation, the first charge of the battery, the formation of a protective film on the anode, called the solid electrolyte intermediate phase layer (SEI), which can prevent the anode and the electrolyte reaction, and is a key element of the safe operation of the battery, high capacity, long life. After several charge and discharge cycles, the battery is aged for 2-3 weeks, the micro-short-circuit battery is removed, and the capacity is sorted and packaged to become a commodity.

Third, battery performance

1, electrical performance:

(1) Rated capacity: 0.5C discharge, single battery discharge time is not less than 2h, battery pack discharge time is not less than 108min (95%);

(2) 1C discharge capacity: 1C discharge, single battery discharge time is not less than 57min (95%), battery pack discharge time is not less than 54min (90%);

(3) Low temperature discharge capacity: 0.5C discharge at -20℃, the discharge time of monomer or battery pack is not less than 72min (60%);

(4) High temperature discharge capacity: 0.5C discharge at 55℃, the discharge time of single battery is not less than 104min (95%), and the discharge time of battery pack is not less than 108min (90%);

(5) Charge retention and recovery ability: shelved at room temperature for 28 days at full charge, charge retention discharge time is not less than 96min (80%), charge recovery discharge time is not less than 108min (90%);

(6) Storage performance: The single battery or battery pack for storage test should be selected from the production date of less than 3 months, the capacity of 50% to 60% before storage, and the environment temperature of 40 ° C ±5 ° C, relative humidity of 45% to 75% environment storage for 90 days. After the storage period is expired, the battery pack is taken out, fully charged at 0.2C and shelving for 1h, and constant discharge at 0.5C to the termination voltage. The above test can be repeated for 3 times, and the discharge time is not less than 72min (60%).

(7) Cycle life: the battery or battery pack is charged by 0.2C and discharged by 0.5C. When the discharge capacity is lower than 72min (60%) for two consecutive times, the test is stopped. The cycle life of the single battery is not less than 600 times, and the cycle life of the battery pack is not less than 500 times.

(8) High temperature shelving life: it should be selected from the single battery with a production date of less than three months for high temperature shelving life test, and should be filled with 50%±5% capacity before shelving, and then shelved under the ambient temperature of 55 ° C ±2 ° C for 7 days. After 7 days, the battery is removed and left for 2 to 5h at an ambient temperature of 20 ° C ±5 ° C. First, the battery is discharged to the termination voltage at 0.5C, and then charged at 0.2C after 0.5h, after 0.5h, and then at 0.5C constant discharge to the termination voltage, and this capacity is used as the recovery capacity. The above steps were repeated for 1 week until the discharge time was less than 72min (60%) in a certain week, and the test was over. Shelf life is not less than 56 days (8-week cycle).

2. Safety performance

(1) Continuous charging: the single battery is charged at 0.2ItA constant current. When the end voltage of the single battery reaches the charging limit voltage, it is charged at constant voltage and kept for 28d. After the test, there should be no leakage, no deflation, no rupture, no fire, no explosion (equivalent to full floating charge).

(2) Overcharge: the single battery is charged with a constant current voltage regulator at 3C constant current, the voltage reaches 10V, and then it is charged at constant voltage, until the battery exploses or fires or the charging time is 90min or the battery surface temperature is stable (the temperature difference within 45min is less than 2℃), and the battery should not catch fire or explode (3C10V); Use a voltage regulator to charge the battery pack at a constant current of 0.5ItA. When the voltage reaches n x 5V (n is the number of single batteries in series), the battery pack is charged at a constant voltage. Stop charging until the battery pack exploses or fires, the charging time is 90 minutes, or the surface temperature of the battery pack is stable (the temperature difference within 45 minutes is less than 2 ° C).

(3) Forced discharge (reverse charge) : the single battery is first discharged at 0.2ItA constant to the termination voltage, and then reverse charge the battery with 1ItA current, requiring that the charging time is not less than 90min, and the battery should not catch fire or explode; Discharge one cell of the battery pack to the termination voltage, and the rest are fully charged batteries, and then stop discharging with 1ItA constant discharge until the voltage of the battery pack is 0V, and the battery should not catch fire or explode.

(4) Short circuit test: the single battery is shorted externally for 90min, or the battery surface temperature is stable (temperature difference within 45min ≤2) to stop short circuit, the external line resistance should be less than 50mΩ, the battery should not fire, do not explode; Connect the positive and negative electrodes of the battery string with a copper wire with a resistance less than 0.1Ω until the battery string voltage is less than 0.2V or the surface temperature of the battery string is stable (the temperature difference within 45 minutes is less than or equal to 2 ° C). No fire or explosion occurs in the battery string

3. Mechanical properties

(1) Extrusion: the single battery is placed in the middle of two extrusion planes, and the pressure is gradually increased to 13kN. The extrusion direction of the cylindrical battery is perpendicular to the vertical axis of the cylindrical axis, and the square battery squeezes the wide and narrow sides of the battery. Each battery can only be squeezed once. The test results shall comply with 4.1.2.1. A steel rod with a diameter of 15cm is placed on the battery pack to squeeze the battery pack on the wide and narrow sides, and the battery pack is squeezed to 85% of the original size of the battery pack, and held for 5 minutes. Each battery pack is only squeezed once.

(2) Acupuncture: The single battery is placed in a steel fixture, and the steel nail of φ3mm ~ φ8mm is used to run through the direction perpendicular to the battery plate (the steel needle stays in the battery) for 90min, or the battery surface temperature is stable (the temperature difference within 45min is less than 2℃).

(3) Heavy impact: the single battery is placed on a steel plane, with a diameter of 15.8mm steel rod flat on the center of the battery, the vertical axis of the steel rod is parallel to the plane, so that the weight of 9.1kg free fall from the height of 610mm on the steel rod in the center of the battery; When the battery is cylindrical, the impact direction is perpendicular to the vertical axis of the cylindrical surface; When a single battery is square, the wide and narrow sides of the battery should be impacted, and each battery can only accept one impact.

(4) mechanical impact; The battery or battery pack is fixed to the test equipment using a rigid fixation method (the method can support all fixed surfaces of the battery or battery pack). One shock of equal value in each of the three perpendicular directions. At least one direction should be ensured to be perpendicular to the wide face of the battery or battery pack, and each shock should be carried out as follows: in the first 3ms, the minimum average acceleration is 735m/s2, and the peak acceleration should be between 1225m /s2 and 1715m /s2.

(5) Vibration: The battery or battery pack is installed directly or through the fixture installed on the shaking table surface for vibration test. The test conditions were frequency 10Hz ~ 55Hz, acceleration 29.4m /s2, frequency sweep cycles of 10 times in each direction of XYZ, and frequency sweep rate of 1oct/min.

(6) Free fall: The single battery or battery pack is freely dropped from a height (lowest height) of 600mm to a 20mm thick hard board on the cement floor, once from each of the three directions XYZ. After the free fall.

4. Environmental adaptability

(1) High temperature baking: Put the single battery into a high temperature explosion-proof box, and heat up to 130℃ at the heating rate of (5±2℃) /min, and hold heat at this temperature for 10min.

(2) High temperature storage: the single battery or battery pack is placed in the oven at 75±2 ° C for 48h, and the battery should not leak, not deflate, not break, not fire, not explode.

(3) Low air pressure: (UL standard).

Lithium battery requirements for components of each group:

1. Requirements for positive and negative materials:

• The positive potential is more positive, and the negative potential is more negative

• High activity (fast response)

• The active substance should be stable in the electrolyte, and the autolysis rate should be small

• The active material should have good electrical conductivity and small resistance

• Easy to produce and rich in resources

2. Selection of conductive agent:

• Excellent electrical conductivity

• Stable chemical composition, low water absorption, easy storage

• Easy to use

At present, the best conductive agent on the market is Japan's Ketjenblack (Kochen Superconducting carbon Black) series of super conductive agents, such as

Ketjenblack ECP and Ketjenblack ECP600JD. Most Japanese manufacturers use this conductive agent.

Koqin superconducting carbon black is mainly supplied by Shanghai Trico Chemical Technology Co., LTD.

3. Requirements for electrolyte

• High conductivity, good diffusion efficiency, low viscosity

• Stable chemical composition, small volatility, easy to store

• Positive and negative active substances can remain stable for a long time in electrohydraulic

• Easy to use

The outstanding problems existing in electrolyte

• Compatibility with positive and negative poles.

• As the voltage increases, the electrolyte solution decomposes to produce gas, which increases the internal pressure, resulting in an air crash damage to the battery

The antioxidant capacity of the solvent is lower when the operating temperature of the battery is increased.

4. Requirements for diaphragm

• Good stability

• Has a certain mechanical strength and bending resistance, resistance to dendrite penetration

• Good water absorption, pore size, porosity meet the requirements

• Easy to use

5. Requirements for the shell

• High mechanical strength, withstand general impact

• Ability to resist process corrosion