Coating defect types and Solutions:

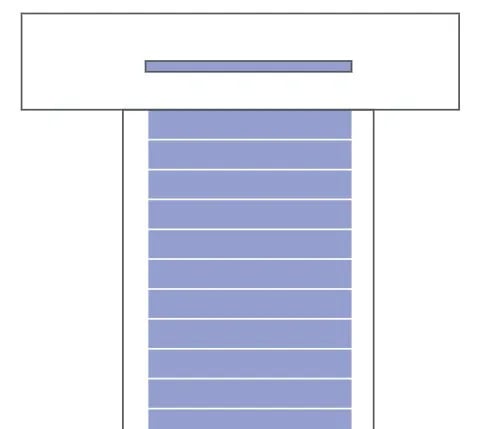

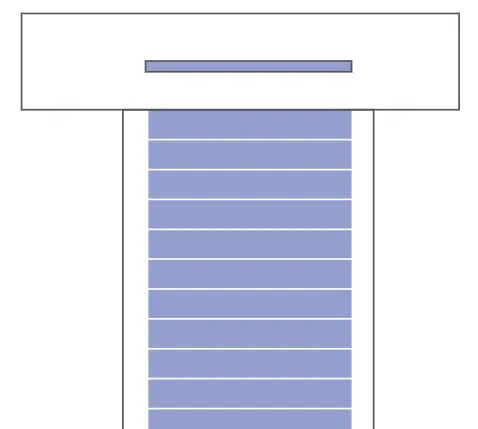

1. Chatter

Features:

Defects occurring across the entire width of the coating.

A line where the thickness of the coating varies compared to the rest of the coating.

Defects occur at uniform intervals or frequencies.

The reason:

Fluid delivery system pressure or flow fluctuations.

Pulsing movement of the base roller/linear table or defects in the roller.

Pressure changes in the upstream vacuum chamber.

Solution:

Replace with a faster transfer rate, such as increasing the feed electrode speed or step rate.

Add a pulse damping element to smooth the output of the pump.

Replace metal pipe with plastic pipe, using its expansion and relaxation properties to smooth pulse.

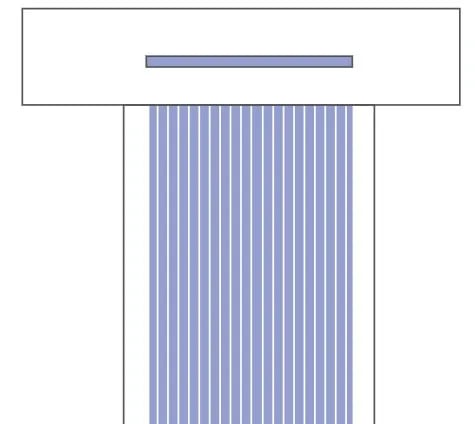

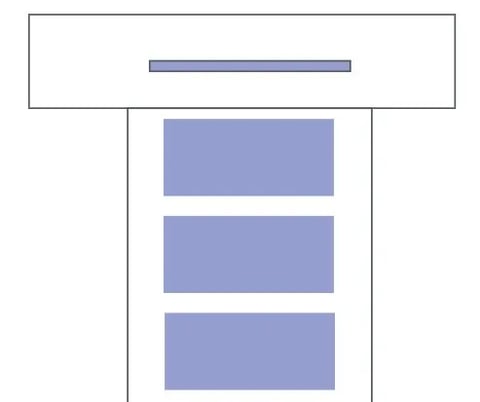

2. Ribbing

Features:

Along the coating length direction, lines appear at regular intervals in the width, and the film thickness decreases.

It usually contains multiple lines across the entire width.

The reason:

High shear force due to fast substrate speed moving dynamic contact points downstream.

Low pressure at the outlet due to low paste viscosity or large gasket thickness.

The upstream pressure is reduced due to the wide gap between the substrate and the coating head.

Solution:

Reduce substrate speed to reduce shear force.

Increase solution flow to increase fluid pressure.

Reduce the distance between the upper lip and the substrate to increase fluid pressure.

Reduce the baffle thickness to increase the pressure at the outlet.

Increase the viscosity of the solution to increase the fluid pressure.

Increase the vacuum chamber to increase the upstream pressure gradient.

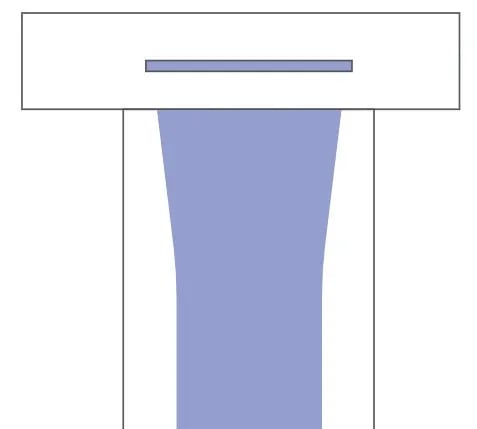

3. Neck defect

Features:

The coating width is gradually reduced.

The edge thickness increases, and as the coating width decreases, the edge thickness increase becomes more pronounced.

The reason:

The change from constrained flow to piston flow results in the change of flow dynamics.

The mismatch between flow rate and substrate speed causes fluid acceleration and shear force.

Solution:

Reduce substrate clearance height to reduce neck defects.

Reduce coating substrate speed to reduce neck defects.

Surfactants are added to reduce neck defects in high surface tension slurries.

4. Edge defects

Features:

The edge thickness of the coating changes, usually as the edge area thickens.

The position of the coating edge changes, and the front and back edges are usually curves rather than straight lines; The side edges may stretch along the length of the coating.

The reason:

The main cause of defects in front and back edge of gap coating.

The surface tension and viscoelastic properties of the slurry cause the edge wet film to move inward during the deposition and drying stages.

The surface energy of different areas on the substrate changes the wettability of the slurry to the surface.

Solution:

Change the edge by changing the machining process by deliberately breaking the bead at the end.

The definition of coating edges can be improved by treating the substrate surface at a specific location to hold the wet film in place.

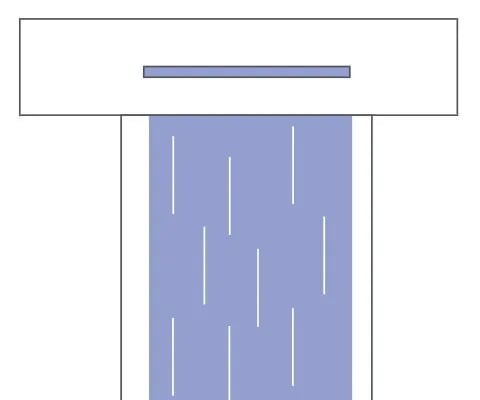

5. Vertical walkways

Features:

A single line defect that begins at a point and extends upstream.

Thin lines in the direction of coating length, reduced thickness.

The reason:

Dust or dirt particles on the substrate impede the slurry flow.

Obstructions on the coated head or lips result in reduced or uncoated areas of extended line thickness.

Damage to the coating head leads to unstable coating beads.

Solution:

Clean the substrate thoroughly to remove dirt and dust.

Increase the flow through the head to reduce residence time, or increase the groove width of the coating head.

Filter and deaerate the stock thoroughly before applying the head.

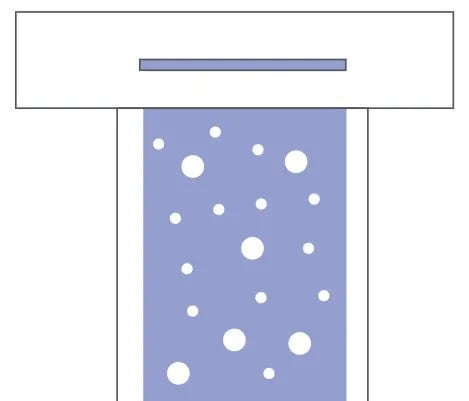

6: Bubbles

Features:

Film defects of round or oval shape, varying in size.

The film thickness at the bubble defect is significantly thinner, or the foil may leak.

The location of defects in the coating width direction is random.

The reason:

Air involvement in the original slurry.

A leak in the fluid delivery system causes air to be sucked in.

The instability of the liquid surface upstream or downstream causes air to be sucked in.

Solution:

Degassing is performed before the solution enters the fluid delivery system.

Check the tightness of all connectors and adapters.

Stabilize the coating window by reducing the gap height to thickness ratio and reduce bubble defects.

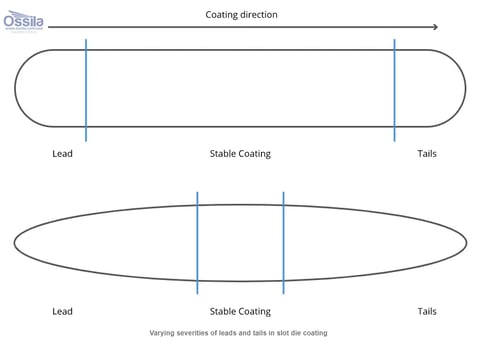

7. Thin head area and tail

Question:

The thin area of the head is the area where the coating does not reach the steady state at the beginning, and the coating thickness does not meet the requirements.

A similar problem occurs at the end of the coating.

Solution:

The coating head is pre-treated and suitable coating conditions are selected