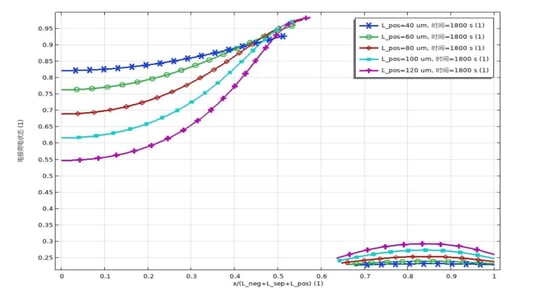

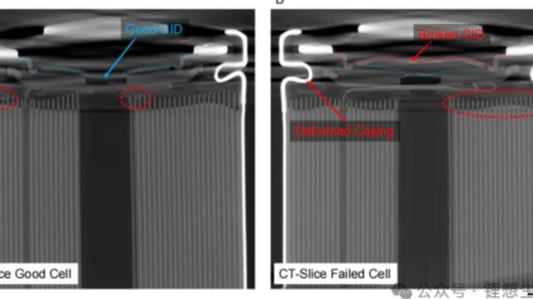

electrode thickness: A Crucial Factor in 4680 Battery DesignAn Introduction to Efficient Battery Design ToolsCOMSOL software enables the creation of a user-friendly battery design app, essential for exploring the impact of electrode thickness on battery performance. The design app simplifies the battery customization process, featuring key functionalities such as parameter reset and calculation.User Interface for Battery Design OptimizationThe electrode thickness impact on performance is central to the app's parameter interface, which requires input of battery model, size, thermal and charge-discharge load parameters. The app allows the selection of cylindrical batteries, specifically customizing them to a 46mm diameter and 80mm height. The volume utilization rate, influenced by electrode thickness, is fine-tuned to align with Tesla 4680 battery specifications, concluding at 91% to approximate a 22.3Ah capacity.Core Components of the 4680 Battery ModelThe model consists of elements vital for examining electrode thickness, including the negative and positive electrode current collectors and coatings, and separators. The design specifies current collector thickness at half of its actual measurement, with the electrode thickness focused on single-sided coatings.Insights from Tesla 4680 Battery DisassemblyDisassembled Tesla 4680 batteries provide reference data on electrode thickness: 15 microns for positive current collector (Al), 8 microns for negative current collector (Cu), 174.4 microns for the positive electrode plate, and 262 microns for the negative electrode plate.Electrode Parameters Influenced by ThicknessDrawing from Tesla's design, the positive electrode uses NMC811. The electrode thickness informs the calculation of active material volumes, assuming a 95% composition. The density of single-sided surfaces, linked to electrode thickness, was determined at 26.58 mg/cm2 for positive and 17.5 mg/cm2 for negative electrodes. Volume fractions derived from electrode thickness data estimate 68.3% for positive and 57.9% for negative materials.Understanding electrode thickness is essential for optimizing 4680 battery design, impacting the performance and efficiency of new-generation batteries.Quote InquiryContact us