PVDF resin is widely used in membrane production due to its high purity and excellent chemical resistance. This allows for the production of membranes that are highly efficient in separating different substances, making them ideal for various industries such as pharmaceuticals, food and beverage, and water treatment.

Durability and Longevity of PVDF Membranes

PVDF resin is known for its exceptional durability and longevity, making it the top choice for membrane production. These membranes can withstand harsh chemicals, high temperatures, and mechanical stresses, ensuring a longer lifespan compared to other materials. This results in cost savings for businesses in the long run.

Efficient Filtration with PVDF Membranes

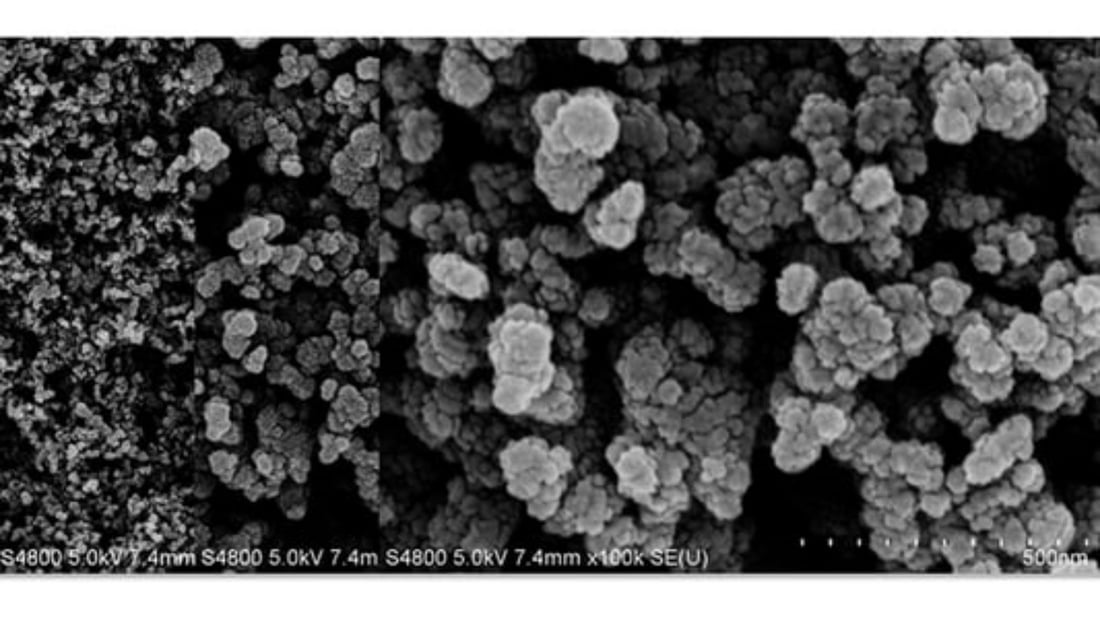

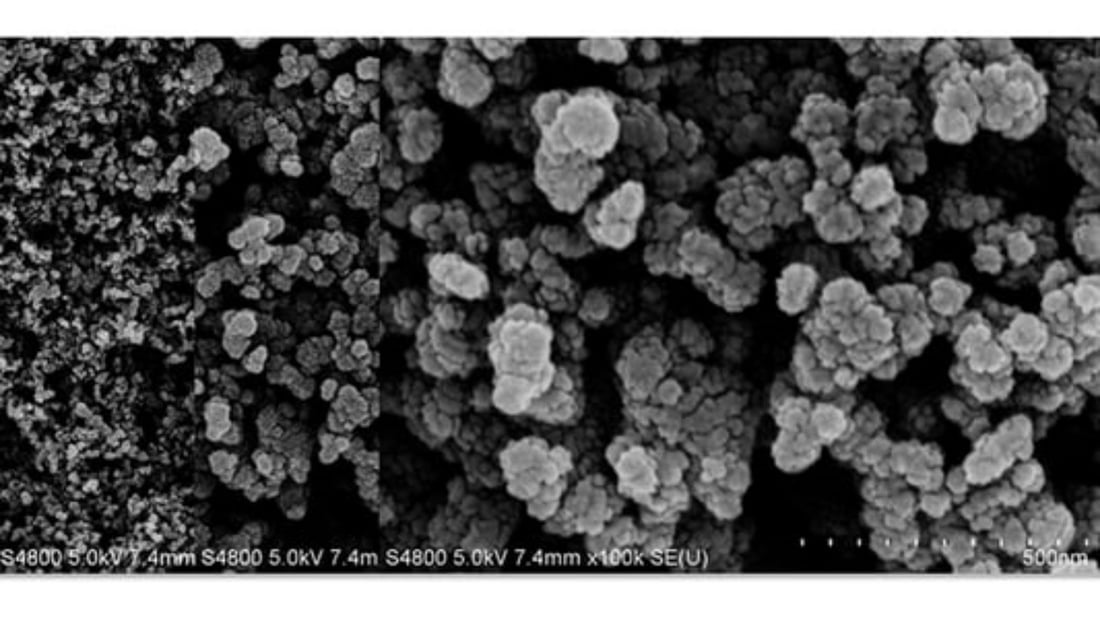

One of the key advantages of using PVDF resin for membrane production is its efficient filtration capabilities. PVDF membranes have a high porosity and surface area, allowing for the effective separation of particles and contaminants from fluids. This results in cleaner and purer end products.

Chemical Compatibility of PVDF Membranes

PVDF resin is known for its excellent chemical compatibility, making it suitable for a wide range of applications. PVDF membranes can be used with various chemicals and solvents without deteriorating, ensuring consistent performance in demanding environments. This versatility makes PVDF membranes highly sought after in the industry.

Resistance to Fouling and Scaling

PVDF membranes are highly resistant to fouling and scaling, making them ideal for continuous operation in industrial settings. The smooth surface of PVDF membranes prevents particles and contaminants from adhering, maintaining high filtration efficiency over time. This reduces maintenance costs and downtime for businesses.

Wide Range of Operating Temperatures

Another benefit of using PVDF resin for membrane production is its wide range of operating temperatures. PVDF membranes can withstand both high and low temperatures, making them suitable for applications in extreme environments. This versatility allows for consistent performance in various settings.

Minimal Maintenance Requirements

PVDF membranes have minimal maintenance requirements due to their strong resistance to fouling and scaling. This saves businesses time and resources on cleaning and upkeep, allowing for continuous operation without frequent interruptions. With PVDF membranes, businesses can focus on their operations without worry.

Customization and Flexibility in Membrane Design

PVDF resin offers flexibility in membrane design, allowing for customization to meet specific requirements. Membranes can be tailored in terms of pore size, thickness, and surface properties to optimize performance for different applications. This versatility makes PVDF membranes adaptable to various industries.

Environmental Benefits of PVDF Membranes

PVDF membranes offer environmental benefits by promoting sustainability in processes such as water treatment and filtration. The efficient separation capabilities of PVDF membranes reduce resource consumption and waste generation, contributing to a greener and more eco-friendly operation. Businesses can enhance their environmental footprint by utilizing PVDF membranes.

Cost-Effectiveness of PVDF Membranes in the Long Run

While PVDF membranes may have a higher initial cost compared to other materials, their durability and longevity make them cost-effective in the long run. Businesses can benefit from reduced maintenance, longer membrane lifespan, and improved operational efficiency with PVDF membranes, resulting in overall savings and increased productivity.

Quote Inquiry

contact us