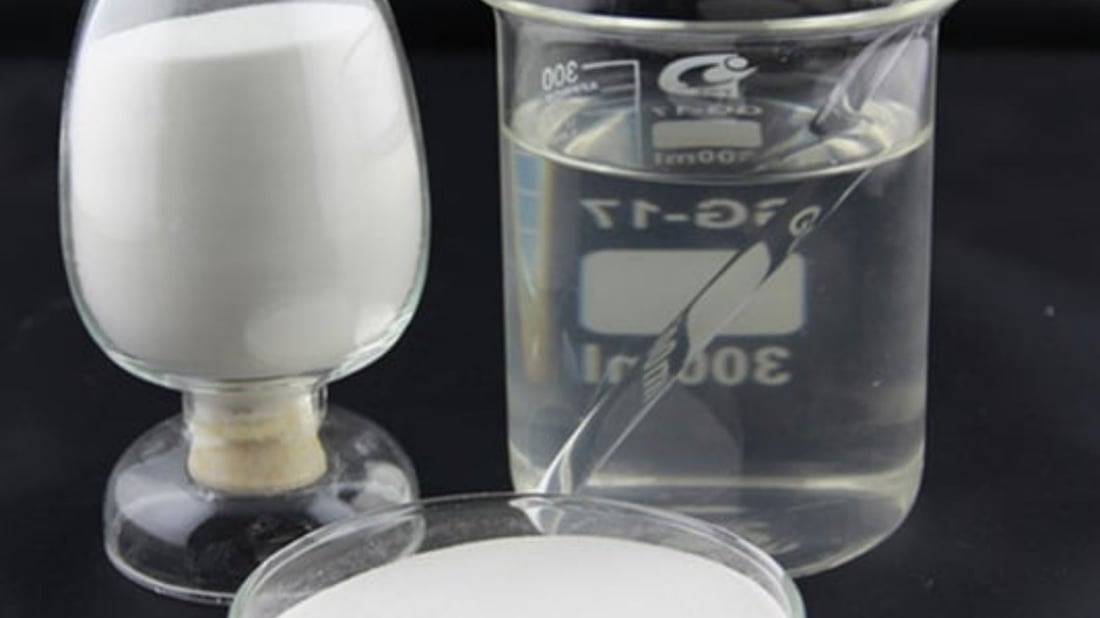

What is PVDF Resin?

Polyvinylidene fluoride (PVDF) resin is a high-performance thermoplastic material known for its excellent chemical resistance. It is often used in applications where exposure to harsh chemicals is a concern, such as in the chemical processing, semiconductor, and pharmaceutical industries.

Chemical Resistance

One of the key advantages of PVDF resin is its exceptional chemical resistance. It can withstand a wide range of corrosive chemicals, including acids, bases, solvents, and oils. This makes it an ideal material for applications that require resistance to harsh environments.

Durability

PVDF resin is highly durable and has excellent weathering resistance. It can withstand exposure to UV radiation, high temperatures, and harsh weather conditions without deteriorating. This durability makes it a reliable material for outdoor applications.

Thermal Stability

PVDF resin has excellent thermal stability, allowing it to maintain its properties over a wide temperature range. It can withstand both high and low temperatures without undergoing significant changes in its chemical structure or physical properties.

Non-Flammable

Another benefit of PVDF resin is its non-flammable nature. It has a low flammability rating, making it a safe choice for applications where fire resistance is important. This property makes it suitable for use in the construction and transportation industries.

Easy to Process

PVDF resin is easy to process using standard techniques such as injection molding, extrusion, and thermoforming. It can be easily molded into complex shapes and structures, making it a versatile material for a wide range of applications. Low Maintenance Due to its chemical resistance and durability, products made from PVDF resin require minimal maintenance. They can withstand harsh operating conditions without deteriorating, reducing the need for frequent repairs or replacements. Biocompatibility PVDF resin is biocompatible, meaning it is safe for use in medical and pharmaceutical applications. It is FDA approved for contact with food and drinking water, making it a trusted material for products that come into contact with the human body. Cost-Effective While PVDF resin may have a higher initial cost compared to other materials, its long-term durability and resistance to chemical degradation make it a cost-effective choice in the long run. Products made from PVDF resin have a longer lifespan, reducing overall maintenance and replacement costs. Wide Range of Applications Due to its excellent chemical resistance and versatility, PVDF resin is used in a variety of industries and applications. From chemical processing equipment to architectural coatings, PVDF resin offers a reliable solution for demanding environments.