Innovative dry electrode process for High Load Graphite Anodes

Breakthrough in Lithium-Ion Battery Efficiency

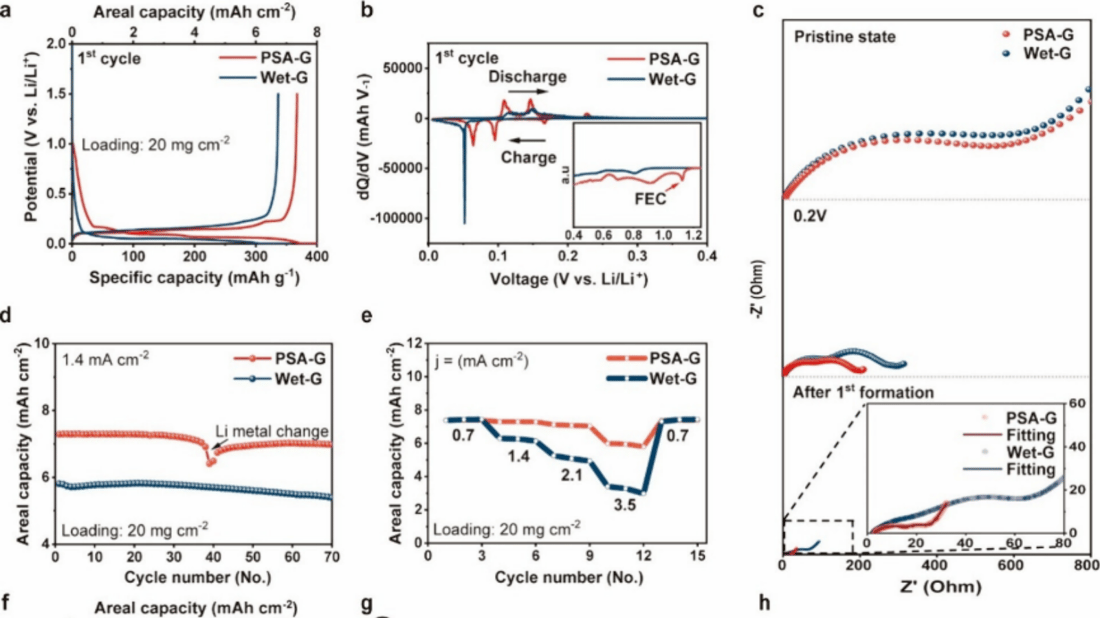

The use of high load electrodes has been identified as a key factor in advancing the energy density of lithium-ion batteries. These high capacity electrodes, however, encounter issues of internal resistance and polarization, which can cap the efficiency of graphite anodes and introduce safety challenges. A revolutionary dry electrode process offers promising solutions for battery enhancement.

Advantages of the Dry Electrode Process

Embracing a solvent-free dry electrode process for fabricating high load electrodes provides significant benefits. Traditionally, PTFE has been employed in establishing open ion transport interfaces, though it's not without its decomposition and environmental drawbacks. By utilizing fluorine-free SBR as a dry coating adhesive, developers achieve a material that is both electrochemically stable and pressure-sensitive, rendering it ideal for ultra-high load graphite anodes.

Composition and Formation of PSA-G Composite Powder

Through a dry electrode process, graphite composite powder known as PSA-G composite powder—comprising SBR and a conductive agent—is synthesized via freeze-drying. This versatile powder is then rolled to create a flexible electrode film, which, once laminated onto copper foil, forms the PSA-G anode.

Structural Insights Via the Dry Electrode Process

Detailed FE-SEM imagery illustrates the transition from initial conductive SBR aggregates dotted across graphite surfaces, to the post-rolling transformation into an adhesive bridge network, augmenting structural integrity.

Optimizing the Dry Electrode Process Activation Pressure

Pressure adjustments during the dry electrode process are crucial for peak performance. Monitoring the electrode surface under varied uniaxial pressures reveals that full PSA-SBR activation occurs at only 1.0 MPa, efficiently promoting powder densification and bolstering mechanical stability, outperforming traditional polymers necessitating high-temperature melting.

Interface Analysis: The Dry Electrode Process Advantage

S-TEM imaging contrasts the interface of PSA-G with wet-prepared graphite anodes (Wet-G). PSA-G anodes, utilizing a dry electrode process, exhibit open channel interfaces, where adhesive bridges discreetly contact graphite, leaving vast areas active. Wet-G anodes, conversely, are uniformly coated, offering stronger coverage yet higher impedance.

This discrepancy underscores the superiority of the dry electrode process in optimizing electrolyte permeability and minimizing anode interface impedance for lithium-ion batteries.