Optimizing Lithium Battery Performance Using direct current internal resistance Testing

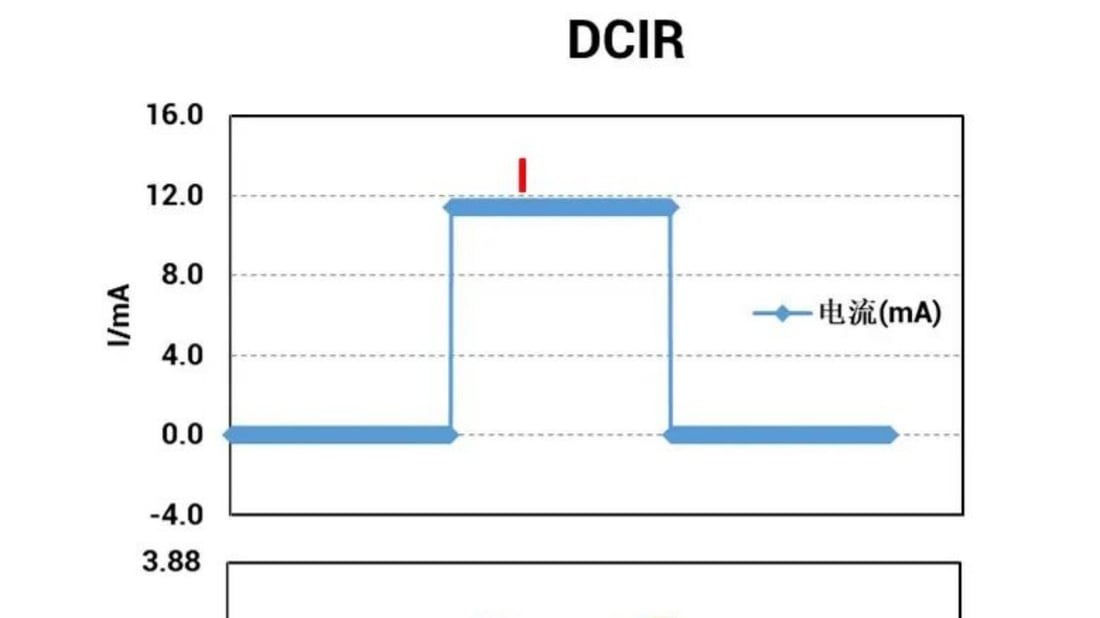

Introduction to Direct Current Internal Resistance

With the rapid adoption of lithium-ion batteries in electric vehicles and energy storage systems, ensuring the uniform performance of each cell in a battery pack has become pivotal. Direct current internal resistance (DCIR) serves as a crucial metric for evaluating the health and power characteristics of batteries. The precision and efficiency of the DCIR testing method directly impact the success of battery sorting and grouping optimization.

Importance of Direct Current Internal Resistance in Battery Modules

Direct current internal resistance measures ion migration and electron conduction resistance within lithium-ion batteries. Deviations in DCIR values, especially over 5%, can lead to uneven current distribution during cycles, hastening local aging and potentially triggering thermal runaway.

Challenges in Traditional DCIR Testing

The conventional direct current internal resistance testing is vulnerable to temperature changes, testing condition fluctuations, and other interferences, leading to inconsistent data. This inconsistency hinders reliable battery pack configuration.

Advancements in DCIR Testing Techniques

A highly consistent DCIR testing approach, leveraging advanced equipment and standardized procedures, can address these challenges. By enhancing the accuracy of direct current internal resistance testing, battery research and production gain reliable support.

Yuanneng Technology's Electrochemical Performance Analyzer

This advanced method utilizes the ERT series testing equipment by Yuanneng Technology. Through improved direct current internal resistance testing precision, the repeatability and comparability of the data see substantial enhancement.

Standardized Processes for Consistent Results

Direct current internal resistance testing, when conducted under streamlined, standardized processes, offers significant improvements in battery performance consistency. By minimizing external interferences, this method provides a robust platform for uniform battery creation.

Conclusion

Implementing a high precision direct current internal resistance testing standard ensures uniform performance across lithium-ion battery cells, resulting in optimized electric vehicle and energy storage applications.