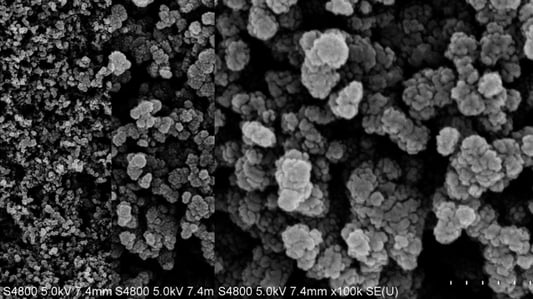

The Significance of Battery Separator CoatingsBattery separator coatings play a crucial role in enhancing the performance and safety of rechargeable batteries. These coatings act as a barrier between the positive and negative electrodes, preventing short circuits and enhancing the overall efficiency of the battery. As technology advances, the demand for high-performance coatings increases, leading to the development of innovative materials such as Emulsion PVDF and Suspension PVDF. In this article, we will explore the performance advantages of Emulsion PVDF over Suspension PVDF for battery separator coatings.1. Improved Porosity and Electrolyte UptakeOne of the key advantages of Emulsion PVDF over Suspension PVDF is its improved porosity. Emulsion PVDF coatings offer a higher degree of porosity, allowing for better electrolyte uptake. This enhanced electrolyte uptake facilitates faster ion transport within the battery, resulting in improved overall battery performance and capacity. The increased porosity of Emulsion PVDF also aids in reducing the internal resistance of the battery, leading to higher energy efficiency.2. Enhanced Mechanical Strength and StabilityEmulsion PVDF demonstrates superior mechanical strength and stability compared to Suspension PVDF. The emulsion process used in the production of Emulsion PVDF creates a more uniform and compact coating structure, resulting in excellent adhesion to the battery separator. This enhanced adhesion provides better resistance to mechanical stress and prevents the coating from shrinking or cracking during battery operation. The improved mechanical strength and stability of Emulsion PVDF contribute to the longevity and reliability of the battery separator.3. Superior Chemical ResistanceEmulsion PVDF exhibits superior chemical resistance compared to Suspension PVDF. This enhanced resistance makes Emulsion PVDF coatings more suitable for batteries that operate in harsh environments or are exposed to corrosive substances. The chemical resistance of Emulsion PVDF ensures the longevity of the battery separator and prevents degradation of its performance over time.4. Excellent Thermal StabilityThermal stability is a critical factor in battery separator coatings, especially in high-temperature applications. Emulsion PVDF offers excellent thermal stability, allowing the battery to operate efficiently even at elevated temperatures. The superior thermal stability of Emulsion PVDF prevents the coating from melting or deforming under extreme heat, ensuring the integrity and safety of the battery.5. Optimal Pore Size DistributionAn optimal pore size distribution is essential for efficient ion transport and electrolyte flow within the battery. Emulsion PVDF coatings exhibit a more uniform and controlled pore size distribution compared to Suspension PVDF. This uniform distribution allows for a consistent flow of electrolyte, minimizing the risk of electrolyte depletion and enhancing the battery's overall performance.6. Improved WettabilityEmulsion PVDF coatings offer enhanced wettability compared to Suspension PVDF. The improved wettability ensures better wet adhesion between the electrolyte and the coating, optimizing the battery's electrochemical performance. The increased wettability of Emulsion PVDF also contributes to quicker and more efficient electrolyte infiltration, improving the battery's overall energy density and cycle life.7. Lower Shrinkage and Improved Dimensional StabilitySuspension PVDF coatings are prone to shrinkage and dimensional instability, which can negatively impact battery performance. Emulsion PVDF, on the other hand, exhibits significantly lower shrinkage and improved dimensional stability. This characteristic ensures that the coating maintains its integrity and adherence to the battery separator, even under varying temperature and humidity conditions.8. Compatibility with Various Battery ChemistriesEmulsion PVDF coatings offer excellent compatibility with a wide range of battery chemistries, including lithium-ion, lithium-polymer, and nickel-metal hydride batteries. This versatility makes Emulsion PVDF a suitable choice for various battery applications, providing manufacturers with flexibility in their battery designs.9. Ease of ApplicationEmulsion PVDF coatings are easier to apply compared to Suspension PVDF. The emulsion process allows for better control over the coating application, resulting in a more uniform and defect-free coating. The ease of application of Emulsion PVDF simplifies the manufacturing process and reduces production costs for battery manufacturers.10. Sustainable and Environmentally FriendlyEmulsion PVDF is considered more sustainable and environmentally friendly compared to Suspension PVDF. The production of Emulsion PVDF consumes less energy and generates fewer greenhouse gas emissions. Additionally, Emulsion PVDF coatings can be easily recycled, contributing to a more sustainable battery manufacturing process.Quote Inquiry